Turbo IS300 5MT and Stock GE!

#91

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

Nice car! Alot of work went to this. I would agree the title needs to change since the motor is no longer a true GE one.

How did you fabricate the LS430 lights into your stock ones? I see the pics but not really understanding the method...plus how did you 'aim' them? making sure they are shooting the road?

Thanks!

Eddie

How did you fabricate the LS430 lights into your stock ones? I see the pics but not really understanding the method...plus how did you 'aim' them? making sure they are shooting the road?

Thanks!

Eddie

For the LS430 retrofit, I did not actually fabricate it, I bought them off a good friend who did it. However I know the retrofit process and it is fairly similar across most headlights:

- Open up the housing and observe available space, aiming mechanisms, and other restrictions such as housing moldings that would need to be "massaged"

- Find a set of projectors that will physically fit within the light housing (the LS430's BARELY fit lol)

- Acquire proper bulbs and ballasts (if needed)

- Find a way to mount said projectors to the reflectors (lots of cutting and trimming involved), while also keeping in mind to make sure the reflectors themselves are at about the middle of their aiming adjustments. This is probably the most difficult part because you also have to make sure the rotational, horizontal and vertical alignments are good as well, which means mocking it up and physically installing it back on the car for a test lighting run against a wall. This can definitely take a few tries... You generally need the light's output to be aligned well enough that the factory adjustment screws can take care of the fine tuning... ofcourse to even be able to adjust them afterwards you have to make sure there is enough room for that whole projector assembly to move within the headlight enclosure.

- Once satisfied, seal the headlights back up with some butyl tape and go for test drives to fine tune the adjustments.

This is over simplified, but that's the general process.

For tons of information about retrofitting and HID lighting in general, I would suggest visiting this forum: www.hidplanet.com

Last edited by exist3nce; 12-09-13 at 07:09 AM.

#92

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

#94

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

More progress here:

My new clutch TS2-XTSS:

R154 ready to go in:

Stock drive shaft modified with a MK3 Supra yoke and u-joint:

R154 installed and shifter centered:

Stay tuned..

My new clutch TS2-XTSS:

R154 ready to go in:

Stock drive shaft modified with a MK3 Supra yoke and u-joint:

R154 installed and shifter centered:

Stay tuned..

#95

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

Finished up all the little things over the past few nights such as:

- Customizing the shifter to sit / angle the way I like it as well as proper height, I'm pretty happy with it now:

- Switched over to Turbosmart FPR1200 regulator from the FPR800

- Relocated AEM EMS water temp sensor to coolant pipe on side of the head from upper rad hose for more accurate and quicker response readings

- Installing the 4 in 1 gauge and it's wiring / sensors:

Oil temp in pan

Trans fluid temp through drain bolt

Night time shot - when parking lights are turned off, gauge switches to white LEDs instead of orange/red

First Impressions of Driving with R154

Ofcourse I had to take it for a little spin to see how it drives... I'm actually pleasantly surprised with how the shifting feels - while not the most elegant it is not as bad as some people have described. The shifts certainly feel heavier than the W series and there's no question the flywheel + clutch setup is heavier thus causing the RPMs to be more lazy when revving up and down. This could be partially solved by a lightweight flywheel, but I went with stock Toyota for now to minimize the chances of running into swap issues. The clutch engages properly with about the same amount of peddle pressure as before, but is much friendlier for slipping off of a stop due to the full face organic material (hopefully it will hold the torque it claims to). As it sits now it is very streetable - even more so than my old setup lol. Oh and an unexpected bonus - my speedo is still accurate within 5% of GPS!! So I won't be needing a Dakota Digital box

- Customizing the shifter to sit / angle the way I like it as well as proper height, I'm pretty happy with it now:

- Switched over to Turbosmart FPR1200 regulator from the FPR800

- Relocated AEM EMS water temp sensor to coolant pipe on side of the head from upper rad hose for more accurate and quicker response readings

- Installing the 4 in 1 gauge and it's wiring / sensors:

Oil temp in pan

Trans fluid temp through drain bolt

Night time shot - when parking lights are turned off, gauge switches to white LEDs instead of orange/red

First Impressions of Driving with R154

Ofcourse I had to take it for a little spin to see how it drives... I'm actually pleasantly surprised with how the shifting feels - while not the most elegant it is not as bad as some people have described. The shifts certainly feel heavier than the W series and there's no question the flywheel + clutch setup is heavier thus causing the RPMs to be more lazy when revving up and down. This could be partially solved by a lightweight flywheel, but I went with stock Toyota for now to minimize the chances of running into swap issues. The clutch engages properly with about the same amount of peddle pressure as before, but is much friendlier for slipping off of a stop due to the full face organic material (hopefully it will hold the torque it claims to). As it sits now it is very streetable - even more so than my old setup lol. Oh and an unexpected bonus - my speedo is still accurate within 5% of GPS!! So I won't be needing a Dakota Digital box

#97

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

Apr. 24, 2014

As a general update I finally took the car out of storage after a brutal winter here.... soooo good to drive it again! R154 seems OK so far, although definitely less refined and more noisy than the W series. For the moment, I'm running at base wastegate spring pressure until I can get a few more items taken care of before turning up the power more...

Next tuning milestone will be for 600whp but first I need:

- stiffer wastegate spring (maybe 9psi)

- AEM 3.5 BAR MAP sensor

- wire ACIS (intake flapper) VSV to AEM for custom control

Hope to post new developments in the next couple weeks.

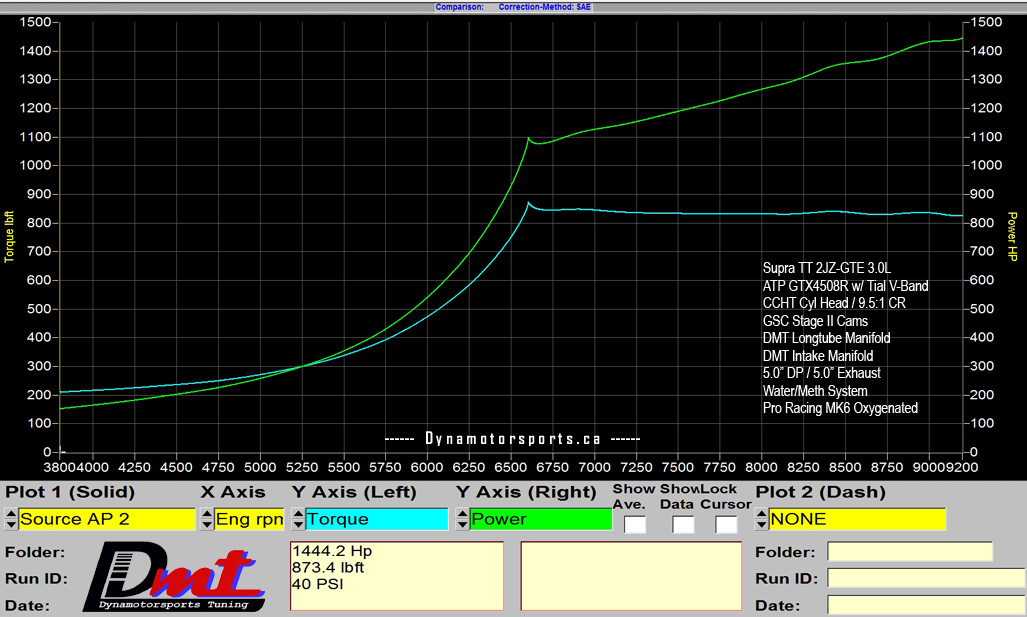

May 9, 2014

After wrapping up the last items, it was back to the dyno for a few hours with more boost and I'm very pleased with the results =)

The car feels fantastic and the new open exhaust sounds amazing. Also note that we recirculated the wastegate dump for a more refined sound and increased rev limit to 8200 RPM.

As a general update I finally took the car out of storage after a brutal winter here.... soooo good to drive it again! R154 seems OK so far, although definitely less refined and more noisy than the W series. For the moment, I'm running at base wastegate spring pressure until I can get a few more items taken care of before turning up the power more...

Next tuning milestone will be for 600whp but first I need:

- stiffer wastegate spring (maybe 9psi)

- AEM 3.5 BAR MAP sensor

- wire ACIS (intake flapper) VSV to AEM for custom control

Hope to post new developments in the next couple weeks.

May 9, 2014

After wrapping up the last items, it was back to the dyno for a few hours with more boost and I'm very pleased with the results =)

The car feels fantastic and the new open exhaust sounds amazing. Also note that we recirculated the wastegate dump for a more refined sound and increased rev limit to 8200 RPM.

Dyno Video

#99

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

My setups have always been designed and geared towards making a flat torque curve to as high an RPM as possible. There are many advantages to making a consistent torque and revving it out provided all the internals can take the RPMs.

Sure I can make more torque in the midrange - but why would I want that? (I purposely prevent it) I would need bigger tires, beefier drivetrain/clutch, etc just to accommodate that "hump" of torque which just dies off as fast as it came. Even my choice of a higher 3.91 diff ratio while most guys are trying to go lower is meant for a high revving car that can pull lots of speed through revving out each gear. Why put the motor and everything else though the stress of any extra torque that I cannot keep all the way to redline?

I've been in many different high HP cars from lumpy domestic V8's to screaming Hondas to 1000whp+ Supras... and I always seem to prefer the ones that don't have their power and torque "die off" the higher they rev. If you can keep torque flat, it's a totally different feeling which is sort of hard to describe... It is less of that initial "torque rush", but basically pulls harder and harder all the way to redline - never giving you the feeling that "its time to shift" because power is falling off.

If you lived closer I'd offer you a firsthand experience lol

The way I set my new power goals is really by torque... realistically for this stage/season I wanted about 400lbft, based on my motor, turbo, fuel system, clutch I wanted to run, etc which I intended to take to 8000rpm, making me 609whp using the simple formula for horsepower. Turns out I made a little under 400lbft near redline but revved a little higher to 8200rpm ending up with 615whp. So all in all I'm very happy with the numbers just the way they are.

Whenever I'm ready for more power, this is type of powerband I will always be striving to achieve

#100

Oh, no, I get it for sure, but with that turbo, there is no reason you can't make at least 100 more lb-ft of torque...

I've ridden and driven both styles... I love high HP cars, but torque is pretty awesome too...

I really don't care so much for super duper high revving engines - give me a power band from 4500 to 7000 and then I don't have to worry about making sure the valvetrain stays together and doesn't float a valve...

Last time I got numbers from my setup, I was on a tinyyyyyy intercooler that was very limiting... will take it out this week sometime and see what happens - I am actually going to turn the boost down 7 psi as I expect it to make significantly more power in the higher rpm band...

I guess the biggest difference is that I know I can turn the boost up and overcome lack of things like cams and whatnot...

I've ridden and driven both styles... I love high HP cars, but torque is pretty awesome too...

I really don't care so much for super duper high revving engines - give me a power band from 4500 to 7000 and then I don't have to worry about making sure the valvetrain stays together and doesn't float a valve...

Last time I got numbers from my setup, I was on a tinyyyyyy intercooler that was very limiting... will take it out this week sometime and see what happens - I am actually going to turn the boost down 7 psi as I expect it to make significantly more power in the higher rpm band...

I guess the biggest difference is that I know I can turn the boost up and overcome lack of things like cams and whatnot...

#101

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

^ Absolutely, I could make another 100 lbft of torque in the midrange (say 5000-6500rpm) but my turbo and the rest of my setup cannot support the HP that torque would generate at 8200rpm. And as I mentioned, I don't care for extra torque that I cannot maintain all the way across to redline..

(500lbft * 6500rpm) / 5252 = 619whp

(500lbft * 8200rpm) / 5252 = 781whp :O

It's just a different way of thinking about power...

Also, in regards to the cams - my main reason for changing them was to allow the motor to breathe better in the higher RPM range. The stock cams provide great performance if you aren't planning to rev much higher than 7000rpm.

(500lbft * 6500rpm) / 5252 = 619whp

(500lbft * 8200rpm) / 5252 = 781whp :O

It's just a different way of thinking about power...

Also, in regards to the cams - my main reason for changing them was to allow the motor to breathe better in the higher RPM range. The stock cams provide great performance if you aren't planning to rev much higher than 7000rpm.

#102

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

So a deal recently came up which I jumped on because it fit with my goal of either building a backup R154 in the background or buying a legit already built one. Option #2 came up first! I want to have something ready in case my stock one takes a dump on me, or I feel that I need more powarr...

Freshly rebuilt R154 by Driftmotion

Includes:

- Driftmotion R154 Rebuild Kit (New bearings, synchros & seals)

- Marlin Crawler 1-2 Billet Shift Fork

- Marlin Crawler Billet Bearing Cover

- Marlin Crawler Billet Thrust Washer

- Driftmotion 3-4 Billet Shift Fork

- Driftmotion 5-R Billet Shift Fork

Here's a pic of the finished product and the old removed parts:

Freshly rebuilt R154 by Driftmotion

Includes:

- Driftmotion R154 Rebuild Kit (New bearings, synchros & seals)

- Marlin Crawler 1-2 Billet Shift Fork

- Marlin Crawler Billet Bearing Cover

- Marlin Crawler Billet Thrust Washer

- Driftmotion 3-4 Billet Shift Fork

- Driftmotion 5-R Billet Shift Fork

Here's a pic of the finished product and the old removed parts:

#104

I love how this thing is in KM and C on the gauges haha so fun. I am in the process of pulling my w55 today, I have a clutch masters 6 puck unsprung, Clutch Masters PP, and Findaza flywheel. Gone through a couple clutches and thought the clunking might been something got loose but as i have pulled the drain plug this is what i saw -------

I might have some questions for you as i too may swap to a r154

I might have some questions for you as i too may swap to a r154

#105

Driver

Thread Starter

Join Date: Jan 2012

Location: Ontario

Posts: 149

Likes: 0

Received 0 Likes

on

0 Posts

I love how this thing is in KM and C on the gauges haha so fun. I am in the process of pulling my w55 today, I have a clutch masters 6 puck unsprung, Clutch Masters PP, and Findaza flywheel. Gone through a couple clutches and thought the clunking might been something got loose but as i have pulled the drain plug this is what i saw -------

I might have some questions for you as i too may swap to a r154

I might have some questions for you as i too may swap to a r154