bolt snapped in hole... what to do?

#1

Pole Position

Thread Starter

well..

just as i was going to warn people of how difficult/tedious it is to remove the tranny pan and put it all back given the number of bolts and limited space, one of the bolts snapped as i was torquing it down. i'm not sure what happened, but the bolt snapped near the head where the threads begin, so the majority of the screw is in the hole. thought i would try to put some super glue and try to attach the pieces but it's not catching, and neither is another bolt i removed to try to use.

no idea what to do right now. obviously can't drive the car now and the screw is pretty thin making it more difficult. already pretty frustrated from the job itself and now i have perhaps a huge problem. trying to stay positive hopefully someone can help me out with this predicament.

just as i was going to warn people of how difficult/tedious it is to remove the tranny pan and put it all back given the number of bolts and limited space, one of the bolts snapped as i was torquing it down. i'm not sure what happened, but the bolt snapped near the head where the threads begin, so the majority of the screw is in the hole. thought i would try to put some super glue and try to attach the pieces but it's not catching, and neither is another bolt i removed to try to use.

no idea what to do right now. obviously can't drive the car now and the screw is pretty thin making it more difficult. already pretty frustrated from the job itself and now i have perhaps a huge problem. trying to stay positive hopefully someone can help me out with this predicament.

#2

You might be able to get it to seal missing one bolt. That would at least make it driveable short term. I never have luck with easy outs (but some guys do). Might be able to grab it with vicegrips when the pan is removed and get it to turn. Welding a bolt to the stub would be difficult in that sensitive area. Which one was it?

#3

Moderator

in-lb right?

Breaking the FIPG the first time can be hard.

The fix now would likely require to separate the pan again. Some bolts pass through to the other side and you may have longer area to catch at the back side.

Worst is you may have to tap a larger size.

Salim

Breaking the FIPG the first time can be hard.

The fix now would likely require to separate the pan again. Some bolts pass through to the other side and you may have longer area to catch at the back side.

Worst is you may have to tap a larger size.

Salim

Last edited by salimshah; 04-10-16 at 05:41 AM.

#4

Pole Position

Thread Starter

You might be able to get it to seal missing one bolt. That would at least make it driveable short term. I never have luck with easy outs (but some guys do). Might be able to grab it with vicegrips when the pan is removed and get it to turn. Welding a bolt to the stub would be difficult in that sensitive area. Which one was it?

i was thinking that too because some gaskets only have 15 bolt holes and are supposed to be compatible. it's the one, where if you're facing the front of the car, is the second one from the front bolt on the left side of the pan (5 bolts from front to back, back being where the drain area is). so if you're facing the front of the car it's on the opposite end of the drain. looks like there's quite a bit of space in between the two adjacent bolts though, on the opposite side there are a flurry of bolts which would seem to be more secure if a bolt were not replaced.

the screw snapped maybe 1/5" inside the shaft so no way using pliers. maybe i'll try gluing something to the end again but i'm a little worried about getting glue on the shaft threads.

Last edited by hsmac; 04-09-16 at 08:32 PM.

#5

Pole Position

Thread Starter

yes in-lbs. seems like a rather high spec. was turning those bolts forever and after they were tight they still turned more and more. i tried criss crossing and not tightening the full amount until balancing the other side, but i was also getting frustrated with the space. thought the torque wrench might be broken but tested it on a lug nut and it clicked. also the last two wrenches i rented didn't lock for some reason (and this one was supposedly new) which made things uncomfortable, but again just having to work above with limited space and not being able to create a level angle made things awkward. again, not sure what happened but what a terrible place for a first time experience.

#7

Moderator

yes in-lbs. seems like a rather high spec. was turning those bolts forever and after they were tight they still turned more and more. i tried criss crossing and not tightening the full amount until balancing the other side, but i was also getting frustrated with the space. thought the torque wrench might be broken but tested it on a lug nut and it clicked. also the last two wrenches i rented didn't lock for some reason (and this one was supposedly new) which made things uncomfortable, but again just having to work above with limited space and not being able to create a level angle made things awkward. again, not sure what happened but what a terrible place for a first time experience.

The pan gasket requires 69 in-lbs ,,, and need the small torque wrench. Human wrist can produce that much torque.

Please confirm that it was not lb-ft which are 12 times higher. If you did then I think we need to tap one size higher for all.

Salim

Trending Topics

#8

Pole Position

Thread Starter

hmm the wheel lugs are 76-78 ft-lb and require med to high torque wrench typically 18 inch or longer arm. You need to put your back into it to produce the torque.

The pan gasket requires 69 in-lbs ,,, and need the small torque wrench. Human wrist can produce that much torque.

Please confirm that it was not lb-ft which are 12 times higher. If you did then I think we need to tap one size higher for all.

Salim

The pan gasket requires 69 in-lbs ,,, and need the small torque wrench. Human wrist can produce that much torque.

Please confirm that it was not lb-ft which are 12 times higher. If you did then I think we need to tap one size higher for all.

Salim

What happened was I read the 8 ft lbs for filter bolts and immediately read the 69 as more torque. Since there is not much torque perhaps it won't leak without the bolt after all.

Last edited by hsmac; 04-09-16 at 11:09 PM.

#9

Pole Position

Thread Starter

Salim you're a genius. It does go through but now I have the problem of figuring out how to catch on to the stuck shaft. Another bolt likely will just spin in place once it meets the other surface right? Maybe I'll try putting a tiny dab of epoxy glue. I figure pushing it out will be easier than reversing it back but who knows.

#10

Pole Position

Thread Starter

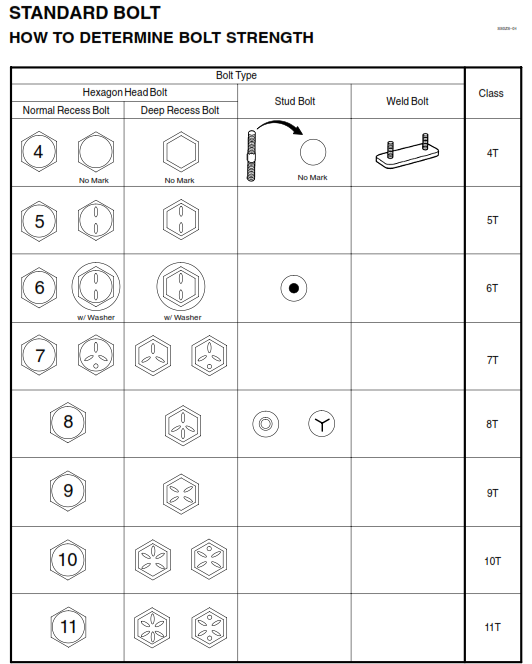

Does anyone know the size of the bolt and where I can get it? Local auto parts or dealet? I think the grade of fasteners at home depot is different from that of automotive fasteners?

I just googled and apparently someone broke that SAME exact bolt. What a coincidence. You guys won't be as dumb as me to overtorque but be careful with that one!

I just googled and apparently someone broke that SAME exact bolt. What a coincidence. You guys won't be as dumb as me to overtorque but be careful with that one!

Last edited by hsmac; 04-09-16 at 10:43 PM.

#11

Does anyone know the size of the bolt and where I can get it? Local auto parts or dealet? I think the grade of fasteners at home depot is different from that of automotive fasteners?

I just googled and apparently someone broke that SAME exact bolt. What a coincidence. You guys won't be as dumb as me to overtorque but be careful with that one!

I just googled and apparently someone broke that SAME exact bolt. What a coincidence. You guys won't be as dumb as me to overtorque but be careful with that one!

#12

iirc they are 10mm heads with 8mm x 1.25 thread. Since its a light torque spec the grade will probably be 9.8 or 10.9 grade. Dealer parts counter should definitely have them. A local auto parts store should have them in the HELP! parts section or you can take a good pan bolt to an ace hardware if you are in a pinch to match up.

#13

Moderator

Salim you're a genius. It does go through but now I have the problem of figuring out how to catch on to the stuck shaft. Another bolt likely will just spin in place once it meets the other surface right? Maybe I'll try putting a tiny dab of epoxy glue. I figure pushing it out will be easier than reversing it back but who knows.

Once you past that hurdle, you will have to determine if the threads on the rest of the bolts are good. Back off each bolt and see if the threads are good and you can torque them to spec. For damages thread in bolt you need to get new bolts and for damaged threads in the holes, you will need to tap to the next size. Best would be get a new bolt to test out the threads in the hole and if you can torque a new bolt to spec, you are good.

If you have more than a few holes to tap then I suggest tap all as this will prevent future problems (which bolt goes with which holes).

To test, just take your current bolt to hardware or auto shop. Assuming your hole threads are good and the bolts are messed up, just buy them from the dealer.

For new I would suggest stainless (or consult auto parts). Make sure you get a matching tap. You can switch to non-metric but I would suggest stay with metric and try to use the same pitch of threads but go a mm size bigger. The application has more to do with rust than anything else, so the strength discussion is purely academic

The gasket will need to be replaced as overtorquing can cause leaks. Overtorquing can also mess-up the pan at the bolt points. If the dimples have been formed then they have to be flattened and pushed back. Use a ruler edge to see if the bolt holes have been pushed in. Hold the metal edge ruler on the the side and use a light source in the back.

Final word is that the level of fluid is higher than the joint. So dont try to slap things together.

Salim

Last edited by salimshah; 04-10-16 at 05:31 AM.

#14

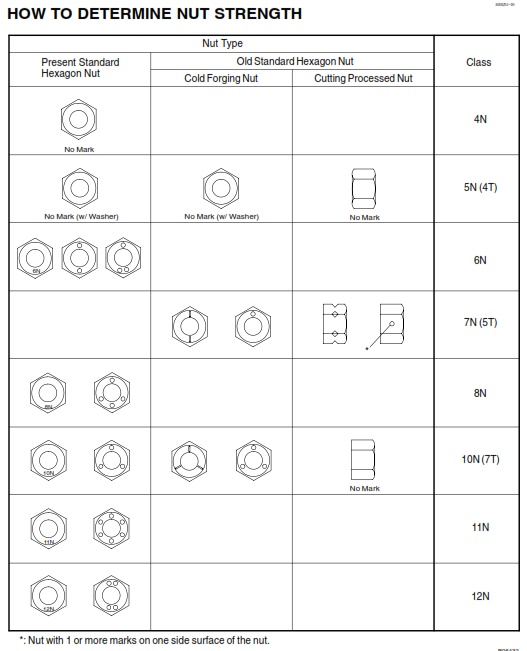

hsmac: I found a schematic that shows how to determine bolt strength based on the markings on the head of the bolt but I can't get it to attach to the post. I'll see if I can PM it to you but if that doesn't work I can e-mail it.

Sometimes I have been able to progressively drill a sheared bolt until I can snap it with pliers and I'm able to remove the post without damage to the threads. Maybe you'll get lucky.

Sometimes I have been able to progressively drill a sheared bolt until I can snap it with pliers and I'm able to remove the post without damage to the threads. Maybe you'll get lucky.