Project Lex (92 Royal Jade SC300)

#934

yeah ... that's why am wondering on some numbers too because they don't match with that of the SF thread on GE / GTE head informations.

how can the non vvti piston have less ( 8 cc) compared to the vvti of 9.5cc ? if you look at both pistons , you will clearly see that the non vvti pistons has more recessed areas so it should have bigger volume

on that SF thread the non vvti has 9.5cc .. so now am confused ..lol

it is good to know though that it looks like that the head which has less recessed area plays a big role on the compression bump

how can the non vvti piston have less ( 8 cc) compared to the vvti of 9.5cc ? if you look at both pistons , you will clearly see that the non vvti pistons has more recessed areas so it should have bigger volume

on that SF thread the non vvti has 9.5cc .. so now am confused ..lol

it is good to know though that it looks like that the head which has less recessed area plays a big role on the compression bump

#935

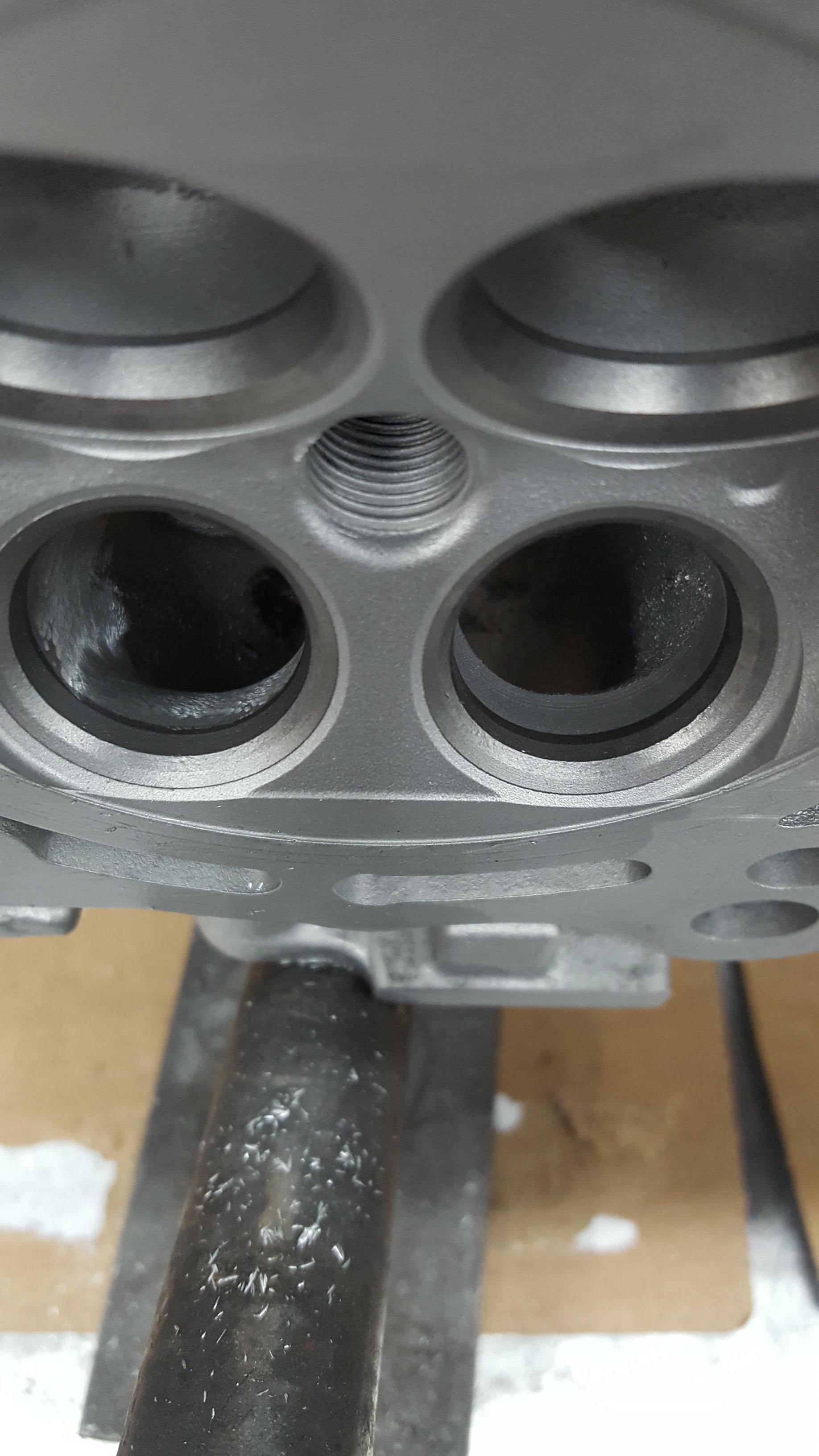

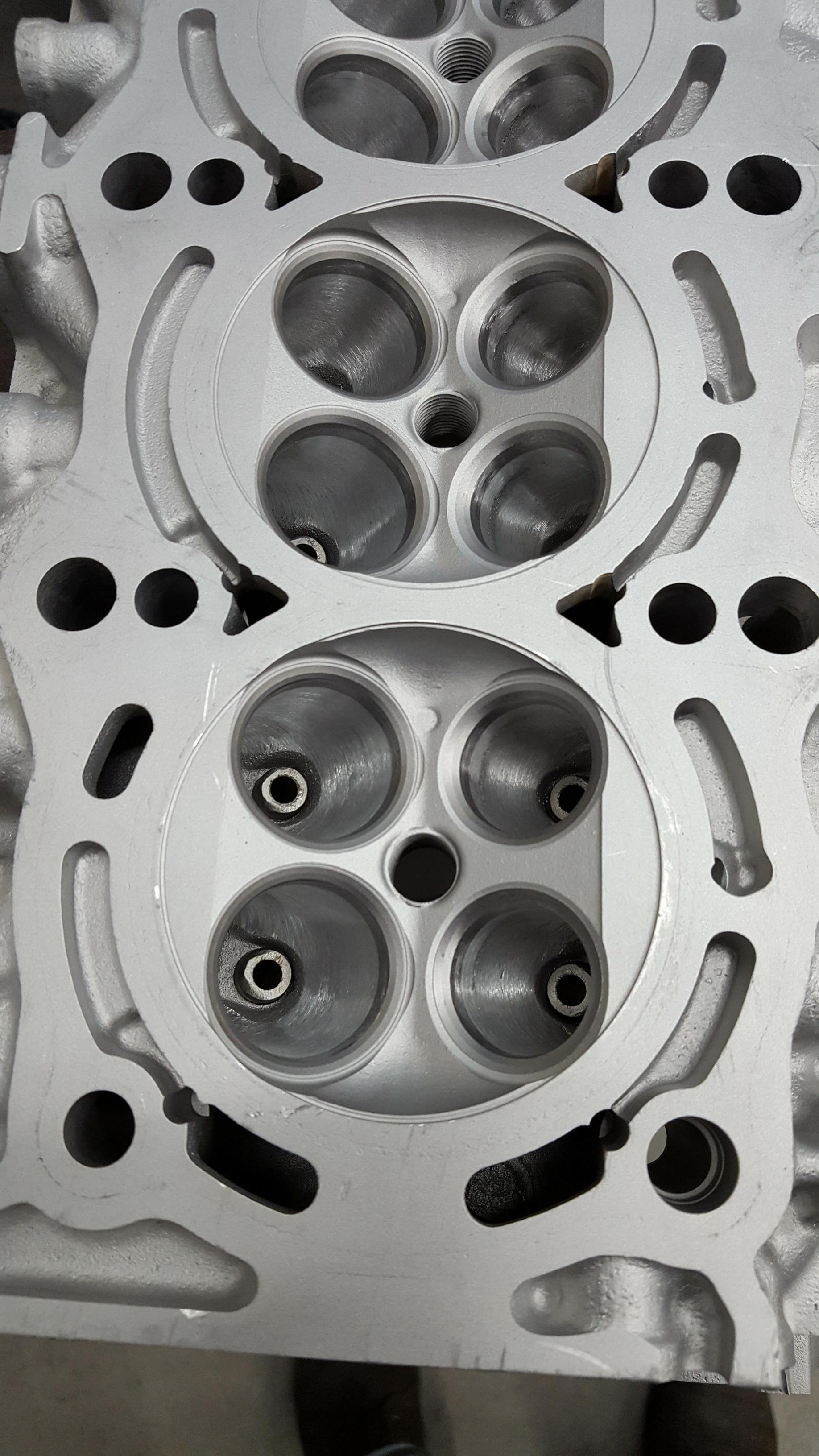

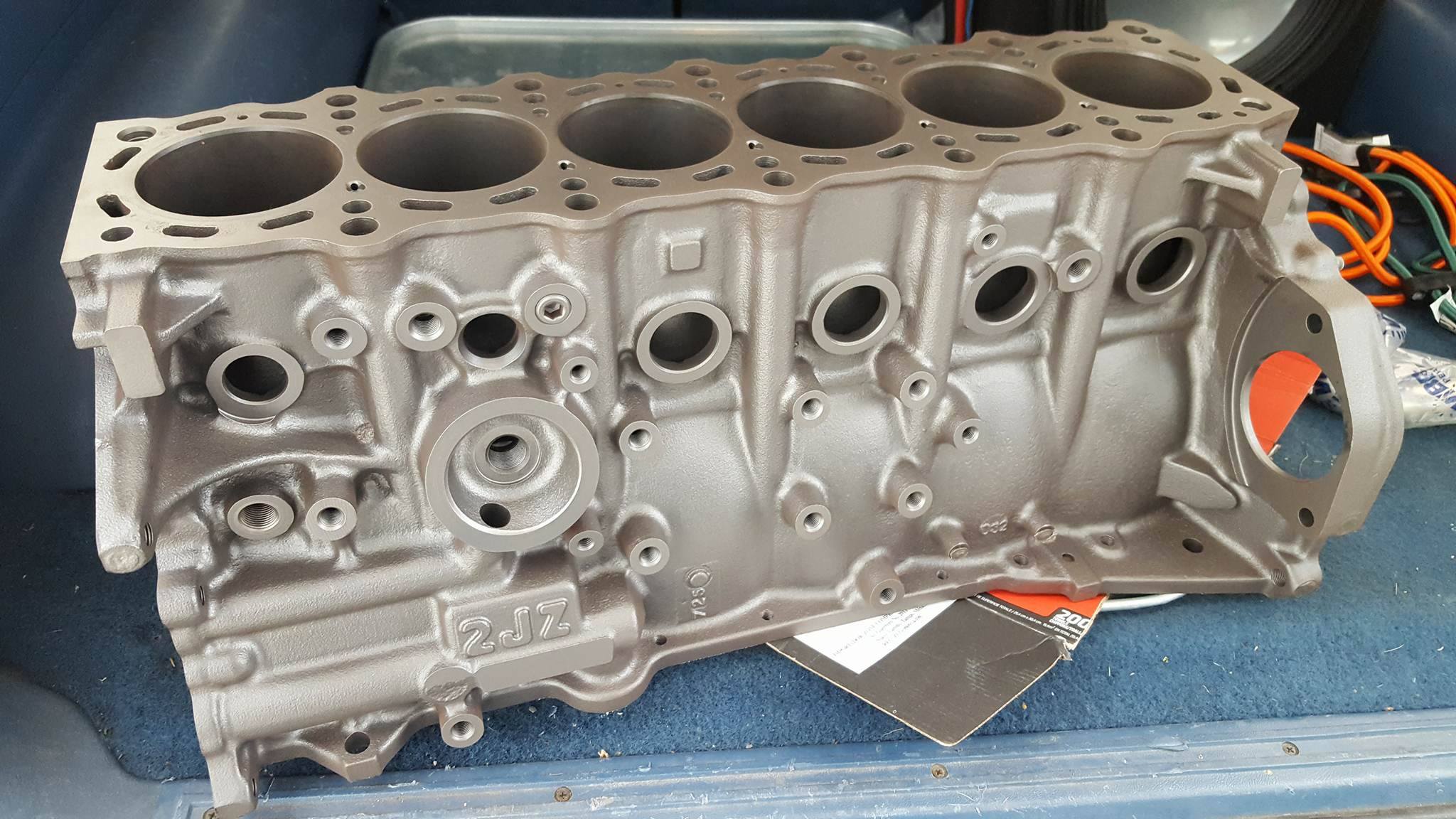

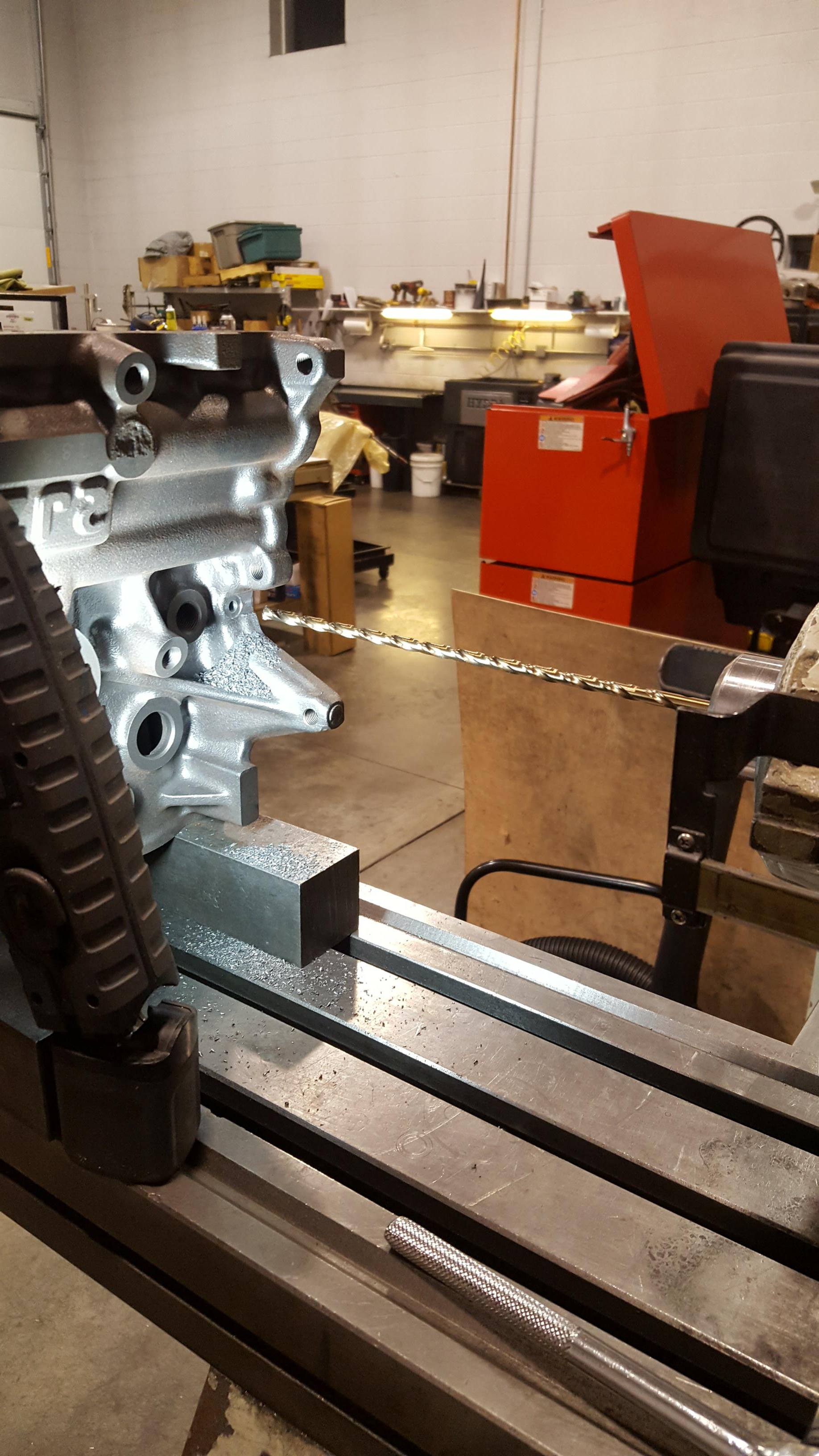

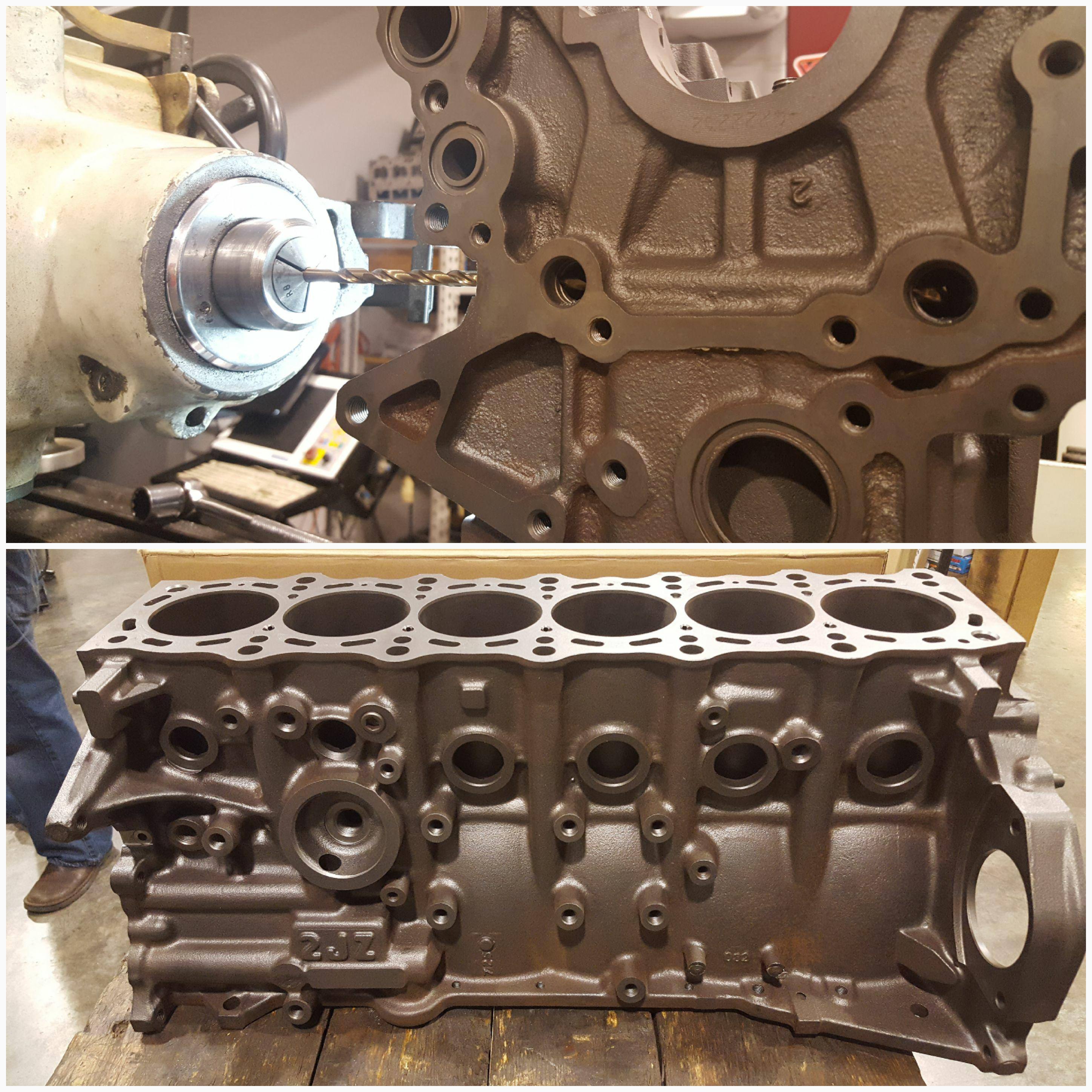

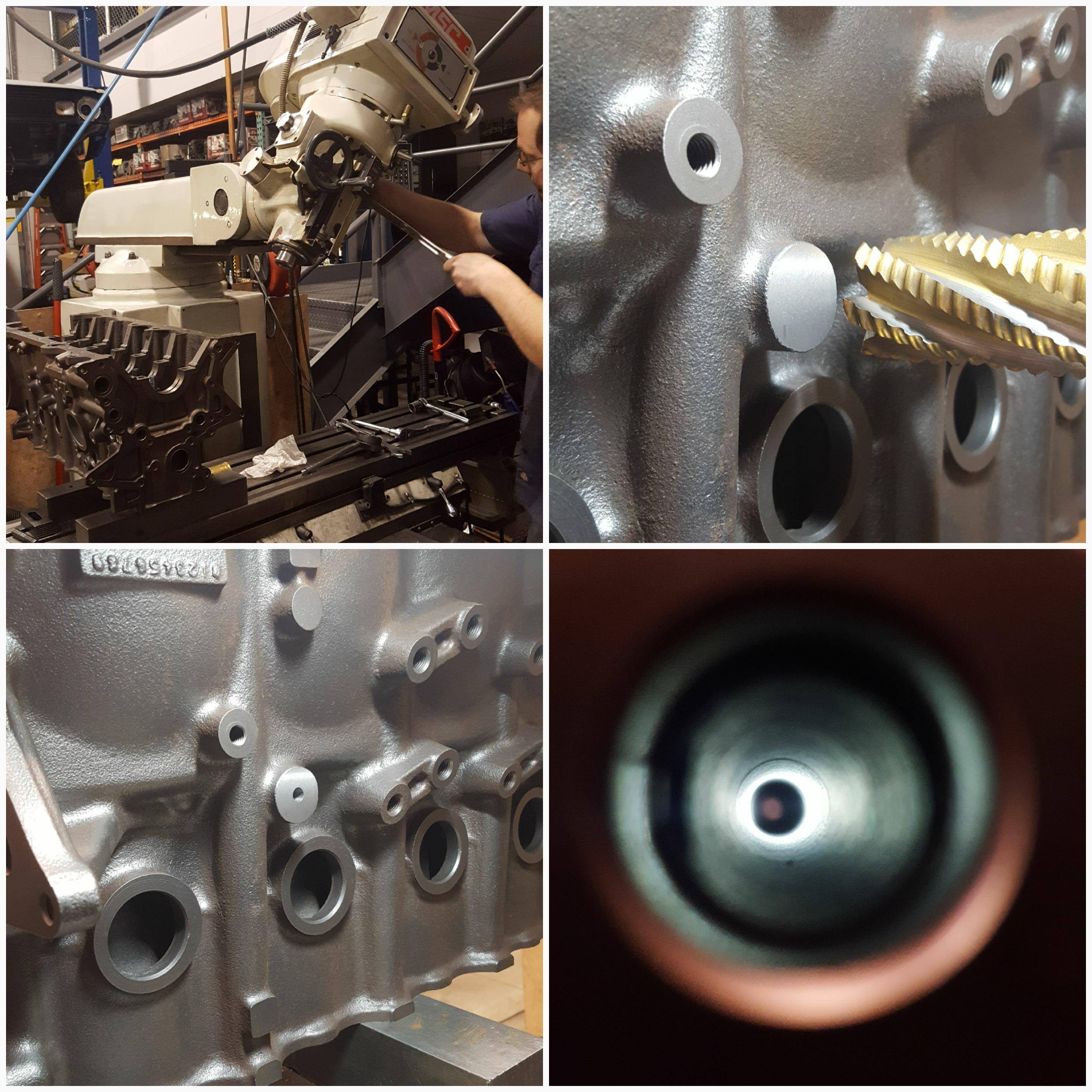

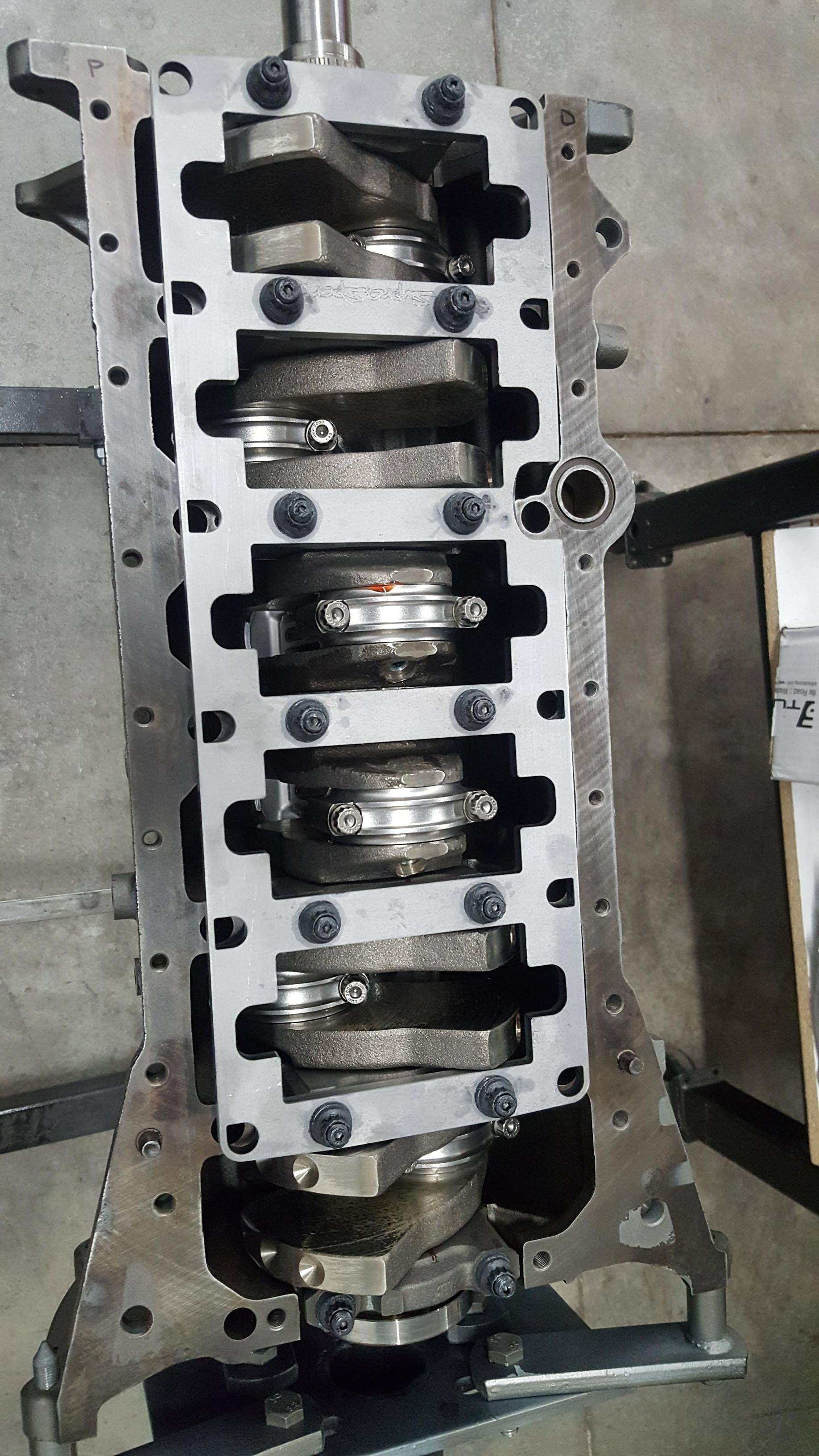

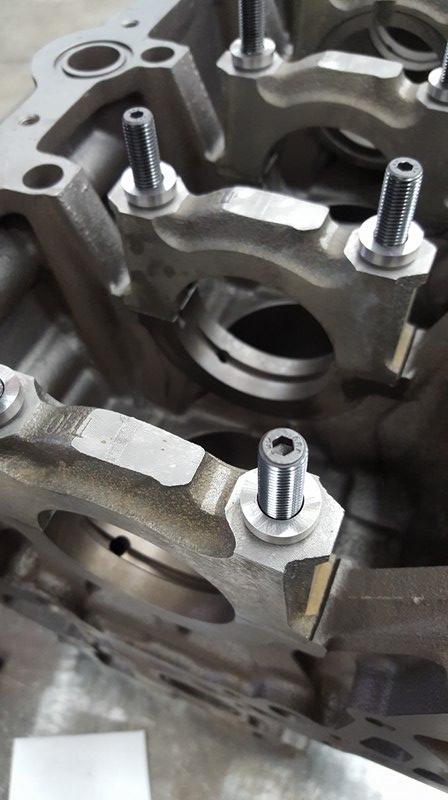

Progress on the motor. They are buttoning up the pocket port on the head. The block they modified for a GTE style oil feed (Exh side) using the worlds longest drill bit, so that'll be nice to be able to run a feed from that side of the motor now instead of a long one crossing over.

Hopefully in a couple more weeks she'll be just about all wrapped up and then it'll be go time! I really like to do my own work, but I have other things I want to get done this winter so the car will likely be dropped off at FenFab with Brett Fenning to do the actual motor swap.

I also picked up a girdle that should help beef up the bottom end. And also picked up a new twin disc setup.

Before:

After:

Motor Oil Feed Mod

Hopefully in a couple more weeks she'll be just about all wrapped up and then it'll be go time! I really like to do my own work, but I have other things I want to get done this winter so the car will likely be dropped off at FenFab with Brett Fenning to do the actual motor swap.

I also picked up a girdle that should help beef up the bottom end. And also picked up a new twin disc setup.

Before:

After:

Motor Oil Feed Mod

#936

Do you have any photos of the girdle, interested in what brand and what is recommended for installation, I'm assuming it requires main studs, but do they require line hone to go with it.

Thanks

Thanks

#937

The girdle kit is from the Supra Store for roughly $350. I don't have any photos as it was delivered directly to my engine builder. But they have lots of photos on their site.

The girdle kit comes with the girdle, spacers, & special sized ARP main studs to work with this setup. There is machining required. My understanding is small flats are typically machined to the tops of the main caps for the girdle to rest on. Spacers are machined to the correct height for it to sit correctly. And yes likely a line hone since you are using studs and changing the clamping characteristics.

The girdle kit comes with the girdle, spacers, & special sized ARP main studs to work with this setup. There is machining required. My understanding is small flats are typically machined to the tops of the main caps for the girdle to rest on. Spacers are machined to the correct height for it to sit correctly. And yes likely a line hone since you are using studs and changing the clamping characteristics.

Last edited by Halon; 12-04-17 at 01:44 PM.

#941

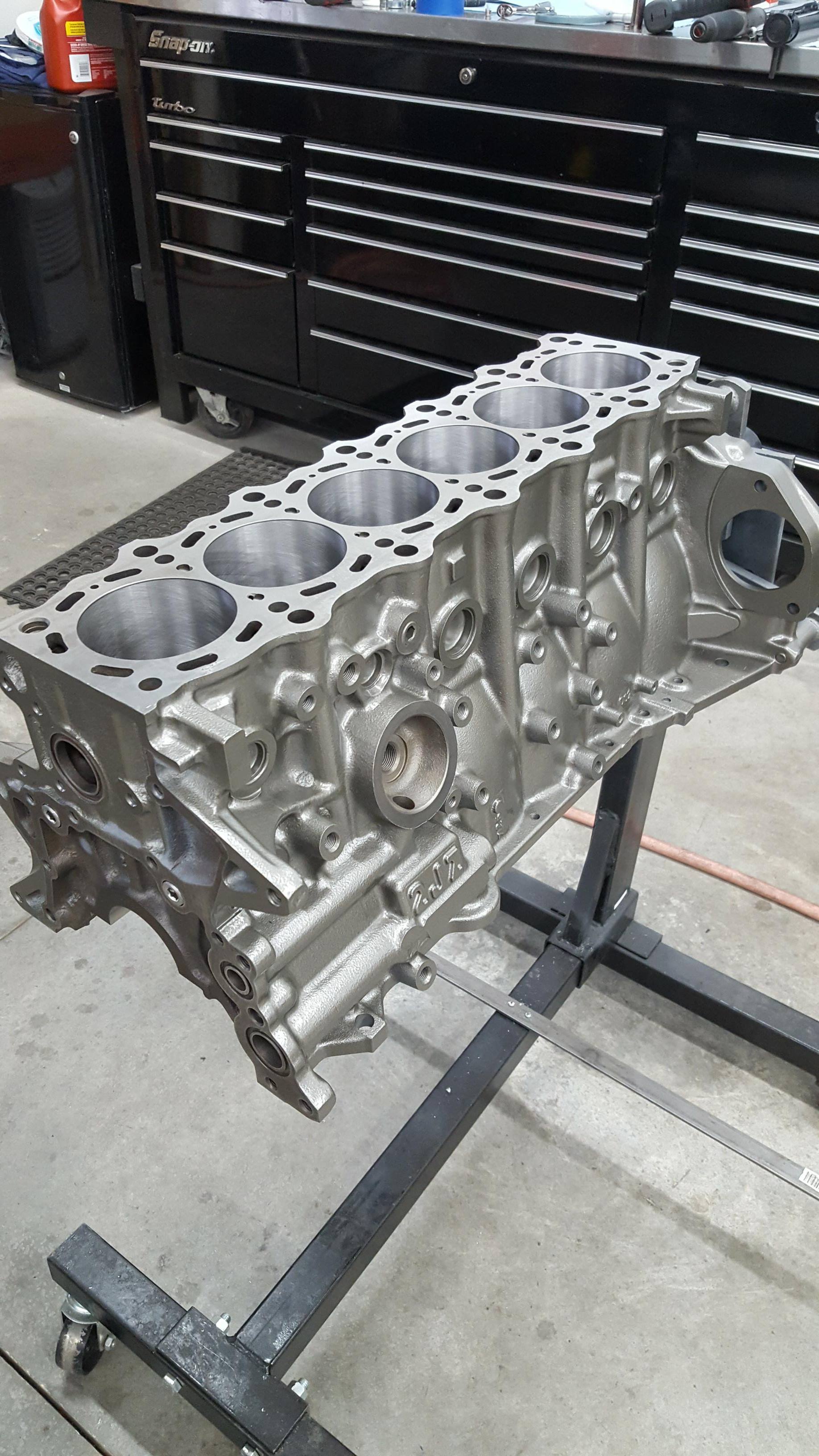

Just about buttoned up. Hopefully pick it up very soon and (*gasp) pay the bill...

I have all the final measurements in place. So based on that I am choosing to run the Cometic MLS .027" thick Head Gasket. In the end based on my rough calculations I will end up with approximately 10.3:1 compression ratio and a .044 squish, which are numbers I'm very happy with.

I have all the final measurements in place. So based on that I am choosing to run the Cometic MLS .027" thick Head Gasket. In the end based on my rough calculations I will end up with approximately 10.3:1 compression ratio and a .044 squish, which are numbers I'm very happy with.

Last edited by Halon; 12-13-17 at 08:09 AM.

#943

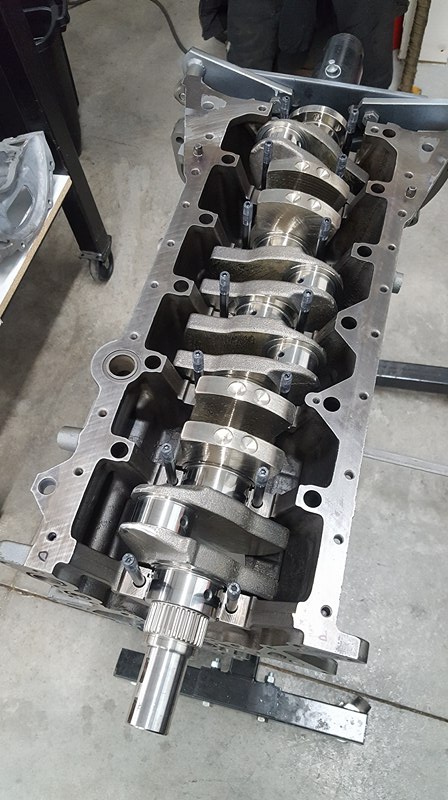

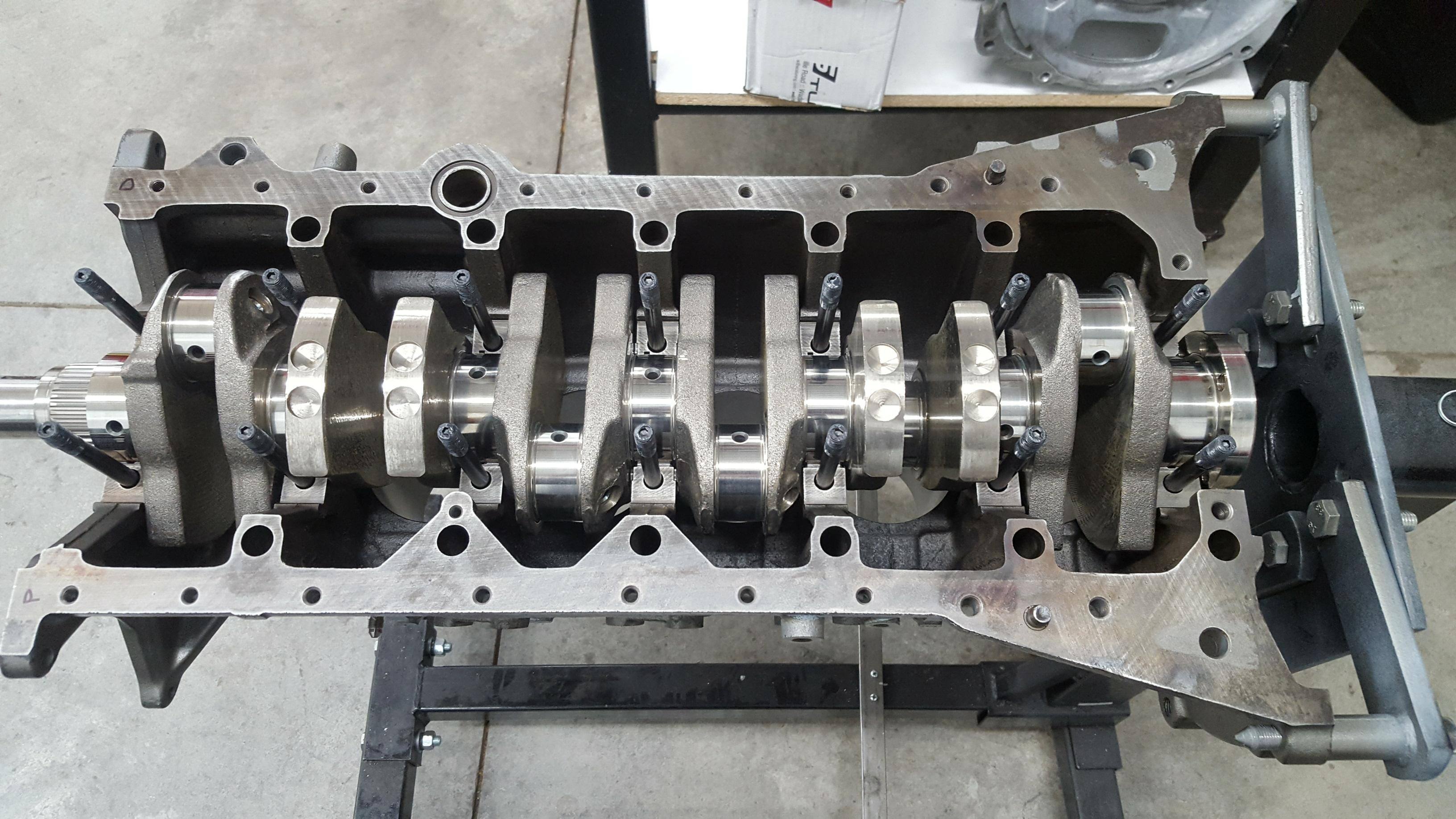

Yeah that's right. Looks like I didn't post a photo, so I'll throw a couple up below this. The way it was explained to me is there's two ways to go about installing the girdle.

First way would be to install it as is, which would basically 'float' the girdle just above the main caps. I was told there might be some minor shaving that would have to be done by hand to knock down some of the peaks of the caps to make sure it floats. That method is nice in that there aren't really any machining costs involved, and you gain the advantage of having all the mains tied together to help against swing in the crank. And that alone does achieve some strengthening of that area.

Second way would be to do like I did. You machine flats on the main caps for the girdle to rest perfectly on. And you then machine the spacers down to that same height and allow for a very slight pre-load up against the main caps. The advantage here is that you not only get the benefit of mitigating swing in the crank, but you've also basically 'thickened' the main caps as well, thus adding strength to the caps themselves. The downside of course is it does require machining, but it's generally advertised that this machining costs less than billet main machining. For reference, I was charged $400 for girdle related machine work. I've never had billet main machine work quoted, but from what I gather it tends to be at least twice that or upwards of $1000.

So just to sum up why I went girdle. First is that I don't think I needed anything at my mediocre power goals (~800). But I am running smaller / fast spooling turbos, plus adding vvti, so it's not just power but it's torque in that low/mid power band that had me just thinking man, if there ever was a time to do something related to the mains, now is the time. So I did the math:

- Billet Mains = Mains ($600) + ARP Main Studs ($130) + Machining ($1000) = $1730 overall cost

- Girdle = Girdle Kit which includes ARP Main Studs ($350) + Machining ($400) = $750 overall cost

Girdle was just less expensive, and for my application/goals I think it is more than enough. So I just pulled the trigger on the girdle.

First way would be to install it as is, which would basically 'float' the girdle just above the main caps. I was told there might be some minor shaving that would have to be done by hand to knock down some of the peaks of the caps to make sure it floats. That method is nice in that there aren't really any machining costs involved, and you gain the advantage of having all the mains tied together to help against swing in the crank. And that alone does achieve some strengthening of that area.

Second way would be to do like I did. You machine flats on the main caps for the girdle to rest perfectly on. And you then machine the spacers down to that same height and allow for a very slight pre-load up against the main caps. The advantage here is that you not only get the benefit of mitigating swing in the crank, but you've also basically 'thickened' the main caps as well, thus adding strength to the caps themselves. The downside of course is it does require machining, but it's generally advertised that this machining costs less than billet main machining. For reference, I was charged $400 for girdle related machine work. I've never had billet main machine work quoted, but from what I gather it tends to be at least twice that or upwards of $1000.

So just to sum up why I went girdle. First is that I don't think I needed anything at my mediocre power goals (~800). But I am running smaller / fast spooling turbos, plus adding vvti, so it's not just power but it's torque in that low/mid power band that had me just thinking man, if there ever was a time to do something related to the mains, now is the time. So I did the math:

- Billet Mains = Mains ($600) + ARP Main Studs ($130) + Machining ($1000) = $1730 overall cost

- Girdle = Girdle Kit which includes ARP Main Studs ($350) + Machining ($400) = $750 overall cost

Girdle was just less expensive, and for my application/goals I think it is more than enough. So I just pulled the trigger on the girdle.

#945

You know that's what he said. He said machining billet mains should not be that much, but that's what I tend to hear thrown around is like 750-1000, and what some of the big shops supposidely charge. He said he wouldn't charge that amount.

Yes they crossed drilled the block for a gte oil feed. He charged me like $50 I beleive, but this was the first time he has done it. Now that he knows what it takes, he will probably be charging twice that now.

Yes they crossed drilled the block for a gte oil feed. He charged me like $50 I beleive, but this was the first time he has done it. Now that he knows what it takes, he will probably be charging twice that now.