Final Calculations after barrel/and or lip change and Tire Rolling Diameters

#1

Pole Position

Thread Starter

Made this a while back...

Before we start, please use Roan's (zeroluxxx) DIY Guide on measuring wheel parts so you get the correct calculation to start out with: [ http://forums.vwvortex.com/zerothread?id=3773369 ]

Maybe this could help some people as I know it can get confusing. Let's start with my wheels as an example:

Fronts:

BBS RS320

17x8 ET43 (7" barrel + .5" center + .5" lip)

Rears:

BBS RS300

17x9 ET53 (7.5" barrel + .5" center + 1" lip)

Adding the center's thickness into the equation only works if your wheels are sandwich mount (lip, face, barrel).

I moved the 1" drop lips from the rear to the front, resulting in:

17x8.5 ET37 (7" barrel + .5" center + 1" lip)

Now how did I get the final offset? Using [ http://www.1010tires.com/WheelOffsetCalculator.asp ]. I input the stock set up (8 ET43) and input the new width (8.5) and got to ET37 to maintain the same inner position because you aren't changing anything except the outer position.

I have noticed for every .5" you go out (pattern), while maintaining the same inner position/clearance, you will lower your offset by ~6mm (6.35mm to be exact (25.4 / 4 = 6.35). I have also noticed the outer position will go out 12mm (using the calculator, it gives you 12mm) (12.7 to be exact; 25.4 / 2 = 12.7)).

Then I got 1.5" lips to replace on the rears resulting in:

17x9.5 ET47 (7.5" barrel + .5" center + 1.5" lip)

Now what about if I changed the barrels up? You'd see the same pattern, but the outer position stays the same, whilst the inner position goes in or out (depending if you get smaller or larger barrels, of course).

Let's use my stock fronts for example (17x8 ET43 with a 7" barrel):

I'll put a 6.5" barrel on it, resulting in: 17x7.5 ET37 (6.5" barrel + .5" center + .5" lip). Notice the pattern again; .5" on that inner position results in 6mm lower offset (again, technically 6.35mm, easier to round down). Same thing with the inner position, it would gain 12mm (12.7 to be exact).

Well, what if I do both [smaller barrels and bigger lips]? You basically use the same formula/input the same things, but one at a time.

For example, lets use the stock fronts again but put .5" smaller barrels and a 1.5" lip on it.

Stock we know is 17x8 ET43 (7" barrel, .5" center + .5" = 8")

.5" smaller barrels we know results in 17x7.5 ET37 (6.5" + .5" + .5" = 7.5)

Now lets add that 1.5" lip to the equation: 6.5 + .5 + 1.5 = 8.5"

Final specs would be: 17x8.5 ET24 (which would gain 12mm inner clearance and outer position would "poke" 26mm more than stock lips).

Hope this helps

Disclaimer: I am not in the tire manufacturing business, but this is the information I have gathered and researched.

In short, not on rolling diameters. I have seen people post up that stretched tires change the overall rolling diameter ("Look at the tire, the sidewall is a triangle now!! It must be taller!). That is incorrect. It does, however, change the Section Width.

I found some good information off Tire Rack that says [http://www.tirerack.com/tires/tirete...sectionwidth]:

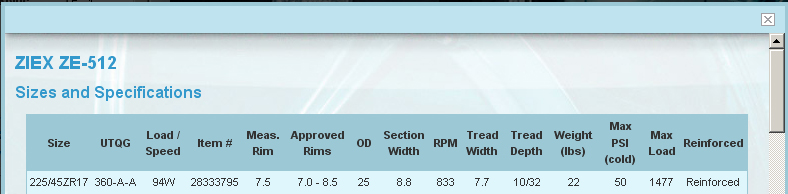

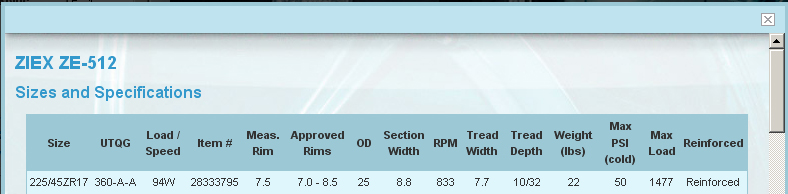

Let's take an example of a common MK4 size and Tire: Falken Ziex 512 225/45/17

Here is how you calculate the OD (Outer Diameter, AKA: Rolling Diameter):

Width x Aspect Ratio = Section Height

Section Height x 2 = Combined Section Height

Combined Section Height + Wheel Diameter = Tire Diameter

225 x .45 = 101.25mm

101.25 x 2 = 202.5mm

202.5 + 431.8 (17x25.4) = 634.3mm / 25.4 = 24.97 inches

As you see from Falken, the 512 in 225/45/17 measures 25" total. That is a +/- .03" variance in the measurement.

However, they measured it from a 7.5" wide wheel with a section width of 8.8". What about if you put that on a stock LB/Monte that measures 7" wide? What about a wider wheel?

Let's see how that changes...

Note 225mm is 8.85 inches (225 / 25.4).

Wheel Width...Section Width Measurement

7"..................8.6"

7.5"...............8.8"

8"..................9.0"

8.5"...............9.2"

9"..................9.4"

9.5"...............9.6"

10"................9.8"

10.5".............10"

So, stretching tires, do increase the section width because you are widening the mounting point the tire beads are on, but the overall diameter, which most people are concerned about, does not have any (or any important/noticeable) change because it is maintained by the steel belts within the tire itself and you cannot add/remove physical material by stretching a tire.

PS: Remember that wheel widths are always measured from inside bead to inside bead. Overall widths are 1" wider (.5" bead on each side). So if you want to know what would "stretch" on a wheel, you need to account for the wheel beads so you can see if the tire will bubble over the beads or it would stretch.

Before we start, please use Roan's (zeroluxxx) DIY Guide on measuring wheel parts so you get the correct calculation to start out with: [ http://forums.vwvortex.com/zerothread?id=3773369 ]

Maybe this could help some people as I know it can get confusing. Let's start with my wheels as an example:

Fronts:

BBS RS320

17x8 ET43 (7" barrel + .5" center + .5" lip)

Rears:

BBS RS300

17x9 ET53 (7.5" barrel + .5" center + 1" lip)

Adding the center's thickness into the equation only works if your wheels are sandwich mount (lip, face, barrel).

I moved the 1" drop lips from the rear to the front, resulting in:

17x8.5 ET37 (7" barrel + .5" center + 1" lip)

Now how did I get the final offset? Using [ http://www.1010tires.com/WheelOffsetCalculator.asp ]. I input the stock set up (8 ET43) and input the new width (8.5) and got to ET37 to maintain the same inner position because you aren't changing anything except the outer position.

I have noticed for every .5" you go out (pattern), while maintaining the same inner position/clearance, you will lower your offset by ~6mm (6.35mm to be exact (25.4 / 4 = 6.35). I have also noticed the outer position will go out 12mm (using the calculator, it gives you 12mm) (12.7 to be exact; 25.4 / 2 = 12.7)).

Then I got 1.5" lips to replace on the rears resulting in:

17x9.5 ET47 (7.5" barrel + .5" center + 1.5" lip)

Now what about if I changed the barrels up? You'd see the same pattern, but the outer position stays the same, whilst the inner position goes in or out (depending if you get smaller or larger barrels, of course).

Let's use my stock fronts for example (17x8 ET43 with a 7" barrel):

I'll put a 6.5" barrel on it, resulting in: 17x7.5 ET37 (6.5" barrel + .5" center + .5" lip). Notice the pattern again; .5" on that inner position results in 6mm lower offset (again, technically 6.35mm, easier to round down). Same thing with the inner position, it would gain 12mm (12.7 to be exact).

Well, what if I do both [smaller barrels and bigger lips]? You basically use the same formula/input the same things, but one at a time.

For example, lets use the stock fronts again but put .5" smaller barrels and a 1.5" lip on it.

Stock we know is 17x8 ET43 (7" barrel, .5" center + .5" = 8")

.5" smaller barrels we know results in 17x7.5 ET37 (6.5" + .5" + .5" = 7.5)

Now lets add that 1.5" lip to the equation: 6.5 + .5 + 1.5 = 8.5"

Final specs would be: 17x8.5 ET24 (which would gain 12mm inner clearance and outer position would "poke" 26mm more than stock lips).

Hope this helps

Disclaimer: I am not in the tire manufacturing business, but this is the information I have gathered and researched.

In short, not on rolling diameters. I have seen people post up that stretched tires change the overall rolling diameter ("Look at the tire, the sidewall is a triangle now!! It must be taller!). That is incorrect. It does, however, change the Section Width.

I found some good information off Tire Rack that says [http://www.tirerack.com/tires/tirete...sectionwidth]:

Section Width

A tire's section width (also called "cross section width") is the measurement of the tire's width from its inner sidewall to its outer sidewall (excluding any protective ribs, decorations or raised letters) at the widest point. This measurement is made without any load placed upon the tire and after the tire has been properly mounted on its industry assigned measuring rim and has been inflated and reset to its test pressure after 24 hours.

Because a tire's section width is influenced by the width of the rim upon which the tire is mounted, the correct industry assigned measuring rim width for the tire size being measured must be used.

The width of a tire mounted on a narrow rim would be "narrower" than if the same tire was mounted on a wide rim. NOTE: because the overall diameter of a steel belted radial is determined by the steel belts, there is little, if any, change to the overall diameter of the tire due to differences in rim width.

The industry rule of thumb is that for every 1/2" change in rim width, the tire's section width will correspondingly change by approximately 2/10".

A tire's section width (also called "cross section width") is the measurement of the tire's width from its inner sidewall to its outer sidewall (excluding any protective ribs, decorations or raised letters) at the widest point. This measurement is made without any load placed upon the tire and after the tire has been properly mounted on its industry assigned measuring rim and has been inflated and reset to its test pressure after 24 hours.

Because a tire's section width is influenced by the width of the rim upon which the tire is mounted, the correct industry assigned measuring rim width for the tire size being measured must be used.

The width of a tire mounted on a narrow rim would be "narrower" than if the same tire was mounted on a wide rim. NOTE: because the overall diameter of a steel belted radial is determined by the steel belts, there is little, if any, change to the overall diameter of the tire due to differences in rim width.

The industry rule of thumb is that for every 1/2" change in rim width, the tire's section width will correspondingly change by approximately 2/10".

Here is how you calculate the OD (Outer Diameter, AKA: Rolling Diameter):

Width x Aspect Ratio = Section Height

Section Height x 2 = Combined Section Height

Combined Section Height + Wheel Diameter = Tire Diameter

225 x .45 = 101.25mm

101.25 x 2 = 202.5mm

202.5 + 431.8 (17x25.4) = 634.3mm / 25.4 = 24.97 inches

As you see from Falken, the 512 in 225/45/17 measures 25" total. That is a +/- .03" variance in the measurement.

However, they measured it from a 7.5" wide wheel with a section width of 8.8". What about if you put that on a stock LB/Monte that measures 7" wide? What about a wider wheel?

Let's see how that changes...

Note 225mm is 8.85 inches (225 / 25.4).

The industry rule of thumb is that for every 1/2" change in rim width, the tire's section width will correspondingly change by approximately 2/10".

7"..................8.6"

7.5"...............8.8"

8"..................9.0"

8.5"...............9.2"

9"..................9.4"

9.5"...............9.6"

10"................9.8"

10.5".............10"

So, stretching tires, do increase the section width because you are widening the mounting point the tire beads are on, but the overall diameter, which most people are concerned about, does not have any (or any important/noticeable) change because it is maintained by the steel belts within the tire itself and you cannot add/remove physical material by stretching a tire.

PS: Remember that wheel widths are always measured from inside bead to inside bead. Overall widths are 1" wider (.5" bead on each side). So if you want to know what would "stretch" on a wheel, you need to account for the wheel beads so you can see if the tire will bubble over the beads or it would stretch.

Thread

Thread Starter

Forum

Replies

Last Post

RavSpec

Club Lexus Vendor Marketplace

0

06-27-12 10:27 AM