Help understand differences in brake rotor discs

#1

Rookie

Thread Starter

Ok so apart from drilled, slotted and smooth (where I understand the difference) I have no idea how to pick break discs.

If you look at smooth discs (just as an example) there are some dead cheap one and then there is brembo which has a more premium price, but is there a difference?

Can anyone explaine what I should look at? Does material/coating play a difference? but then thinking about it how would I tell the difference in material as all manufacturers just state them as "alloys".

If you look at smooth discs (just as an example) there are some dead cheap one and then there is brembo which has a more premium price, but is there a difference?

Can anyone explaine what I should look at? Does material/coating play a difference? but then thinking about it how would I tell the difference in material as all manufacturers just state them as "alloys".

#2

Differences, number and spacing of cooling fins. Material, high carbon steel being the strongest ( not covering exotic materials). Coatings for the rotor. A high quality zinc coating I think is best. Painted hats I find flake and rust. Uncoated ones rust in days.

#3

Racer

iTrader: (1)

First, there is no such thing as a high carbon steel brake rotor. High carbon steel is used for things like knives and cutting instruments. Rotors are made mainly of cast iron. Some "composite" rotors have a steel hat or the part that interfaces with the hub. fully cast rotors dissipate heat better than composite rotors and are more common. The composite rotor is slightly lighter. All rotors other than exotic use cast iron as the brake surface. There are a number of ways of coating the hat portion of the rotor. I have used Centric rotors for years and they are powder coated and I have never had one flake. If it were me, I would get an OEM or Centric rotor. Both are high quality and should last a long time. I would stay away from "composite' rotors. There are a number of other quality rotors on the market such as Brembo. For our cars the slotted and drilled rotors a pretty much just eye candy.

#6

Racer

iTrader: (1)

Read about rotors online and make an informed decision. Here is one, http://www.centricparts.com/products/hcr high carbon rotors are superior .

#7

Lexus Test Driver

I will give you my observations and impressions. but not on my SC430. I did change the brake pads on my SC430 and left the stock OEM rotors on the car. I chose Power Stop Z23 pads and noticed better stopping power. How much, not sure.

now, my 2000 Trans Am convertible with a 5.7L V8 had slotted and drilled rotors with Z17 ceramic pads. Turns out they were all from Power Stop. The car also came with 17in wheels but now has 18 and 19 inch wheels. The car did not stop well due to the additional weight.

i changed the pads to the Power Stop Z26 carbon fiber pads...it made a difference but I still wasn't happy. I just changed the rotors to the Centric rotors Cole displayed. The are blanks and look OEM, but WOW, what a nice change. The Z26 pads bite much better with the new rotors and I am now happy with the braking.

now, my 2000 Trans Am convertible with a 5.7L V8 had slotted and drilled rotors with Z17 ceramic pads. Turns out they were all from Power Stop. The car also came with 17in wheels but now has 18 and 19 inch wheels. The car did not stop well due to the additional weight.

i changed the pads to the Power Stop Z26 carbon fiber pads...it made a difference but I still wasn't happy. I just changed the rotors to the Centric rotors Cole displayed. The are blanks and look OEM, but WOW, what a nice change. The Z26 pads bite much better with the new rotors and I am now happy with the braking.

Trending Topics

#9

Racer

iTrader: (1)

Coleroad your post said high carbon steel. The info you provide makes no mention of the material being steel, just high carbon. There are very few rotors being made with steel. It does not dissipate heat well. It is almost always iron. Even the Centric info you provide in the previous post makes no mention of the rotor surface being steel.

#10

Once you add the high amount of carbon to iron, you have steel. http://www.differencebetween.info/di...iron-and-steel. They just chose to call it high carbon alloy. The chromium, molybdenum, in the alloy is one way of adding carbon.

#11

Racer

iTrader: (1)

Sorry alex2016g we hijacked your thread. There are cheap rotors out there. Years ago I purchased a set of Wearever rotors for an Oldsmobile. They had a lifetime warranty so I thought, why not. They had no coating on them and rusted immediately. I only could get about 10K miles out of them and was eventually told they are composite rotors. They were cheap but I eventually changed them. I think if you get any of the reputable companies you will be fine. No need for anything exotic. I hope that answers your question.

#12

Rookie

Thread Starter

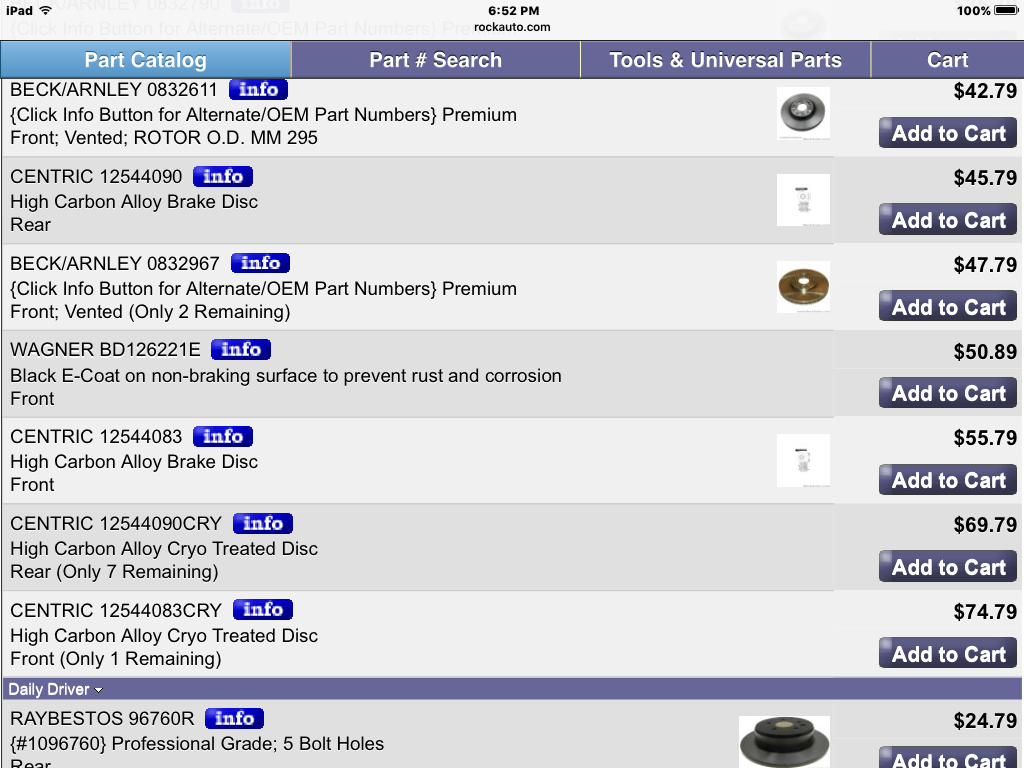

Thank you all for the help. It has been very educational. Looks like I am going to order the High carbon alloy ones from centric and Power Stop Z23 pads.

Is there a reason why Centric doesnt do slotted in High carbon alloy?

Is there a reason why Centric doesnt do slotted in High carbon alloy?

#14

Racer

iTrader: (1)

Those are two very interesting quotes and kitable is correct. Just to clarify. You don't add carbon to iron to get steel. You drive it off. Steel is has generally less than 2% carbon. Anything above that is considered cast iron or even "pig iron". Why a company would advertise "high carbon rotors" is beyond me. All they are really saying is we use cast iron. Carbon is added in the refining process as an oxidizing agent and is driven off in the blast furnace as either carbon dioxide or slag. A blast furnace forces oxygen through the process to enhance the reduction of carbon. (over simplifying) All the normal rotors that are used in street cars are cast. Steel can be cast, but normally it is either forged,extruded, or machined. Also, cast iron has a much better ability to conduct heat. Another reason not to use steel. Coleroad is also correct that modern brake pad materials do not benefit from drilled or slotted rotors. Personally, I would rather have the added mass to absorb the heat. Just so you know, I grew up in Pittsburgh and have been to US Steel a number of times for field trips in the 60s.