Upper Control Arm Question

#1

Driver School Candidate

Thread Starter

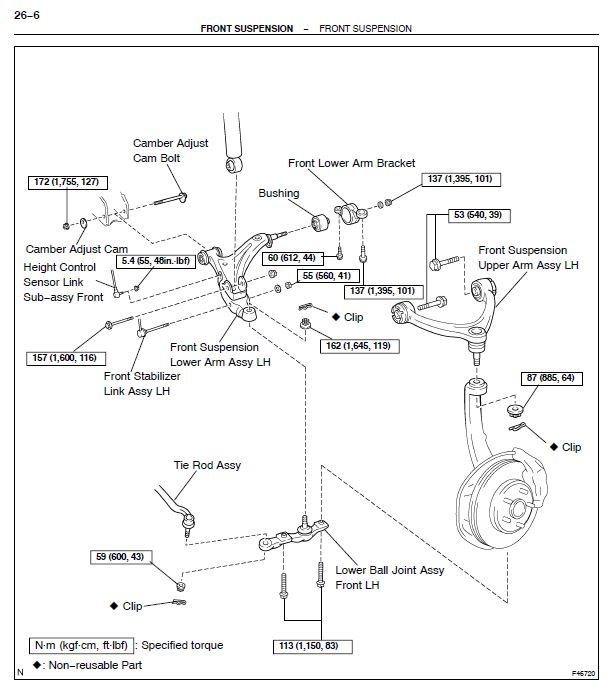

I'm currently in the middle of replacing a bunch of various suspension components, and the UCAs are one of them. I removed the old ones, noting their movement. The driver's side--which had an entirely broken bushing--would rotate up and down, with moderate resistance, on the intact bushing side. The passenger side, with intact bushings, only moves up and down as far as the rubber allows it to, meaning it's not rotating at all on the bolt shafts.

Which way is correct? How tight should the bolts be? Also, if they're meant to be tight enough that it can only rotate up and down as far as the rubber allows--which is minor--how should I position the UCAs when I tighten them?

The strut assemblies are out of the car, and I'm moving to the rest of the parts for the time being. Thanks in advance for any advice!

Which way is correct? How tight should the bolts be? Also, if they're meant to be tight enough that it can only rotate up and down as far as the rubber allows--which is minor--how should I position the UCAs when I tighten them?

The strut assemblies are out of the car, and I'm moving to the rest of the parts for the time being. Thanks in advance for any advice!

#3

Lexus Champion

I'm currently in the middle of replacing a bunch of various suspension components, and the UCAs are one of them. I removed the old ones, noting their movement. The driver's side--which had an entirely broken bushing--would rotate up and down, with moderate resistance, on the intact bushing side. The passenger side, with intact bushings, only moves up and down as far as the rubber allows it to, meaning it's not rotating at all on the bolt shafts.

Which way is correct? How tight should the bolts be? Also, if they're meant to be tight enough that it can only rotate up and down as far as the rubber allows--which is minor--how should I position the UCAs when I tighten them?

The strut assemblies are out of the car, and I'm moving to the rest of the parts for the time being. Thanks in advance for any advice!

Which way is correct? How tight should the bolts be? Also, if they're meant to be tight enough that it can only rotate up and down as far as the rubber allows--which is minor--how should I position the UCAs when I tighten them?

The strut assemblies are out of the car, and I'm moving to the rest of the parts for the time being. Thanks in advance for any advice!

#4

Driver School Candidate

Thread Starter

The only problem, now that I know how much to torque them, is the positioning. If I tighten them to 39 ft-lb, they won't rotate on the bolt. They'll by relatively solidly in place. So I'm not sure, exactly, how to position them.

#5

So I never change UCA on LS, but I did on my SC430. I understand it maybe different car, but like @rkw77080 said, use a torque wrench.

When you said it will not rotate, did you buy an OEM UCA? On my SC430, I bought an UCA from Autozone. Yeah that was a mistake because it will not fit. Maybe I got a bad batch or whatever, but it just wont fit. It seems slightly larger, so it was returned. I wonder if you have the same problem. From what I can remember when working on my SC (it has been a while), it will rotate, but firm, not loose. I ended up with OEM UCA.

When you said it will not rotate, did you buy an OEM UCA? On my SC430, I bought an UCA from Autozone. Yeah that was a mistake because it will not fit. Maybe I got a bad batch or whatever, but it just wont fit. It seems slightly larger, so it was returned. I wonder if you have the same problem. From what I can remember when working on my SC (it has been a while), it will rotate, but firm, not loose. I ended up with OEM UCA.

#6

Lexus Champion

The UCA is designed to move up-and-down in respond to road surface. With the 2 mounting bolts properly torqued, you should still be able to rotate the UCA. You may need to apply some force but don't worry, you cannot hurt it - it is designed to withstand pounding by a vehicle that weights several thousand pounds. Another thing you can do is to spray some WD-40 on the contacting surfaces, but be sure to only do so after you torque down the bolts (lubricating the bolt threads will cause over-torquing of the bolt).

#7

Driver School Candidate

Thread Starter

The UCA is designed to move up-and-down in respond to road surface. With the 2 mounting bolts properly torqued, you should still be able to rotate the UCA. You may need to apply some force but don't worry, you cannot hurt it - it is designed to withstand pounding by a vehicle that weights several thousand pounds. Another thing you can do is to spray some WD-40 on the contacting surfaces, but be sure to only do so after you torque down the bolts (lubricating the bolt threads will cause over-torquing of the bolt).

Trending Topics

#8

Lexus Champion

#9

#10

Driver School Candidate

Thread Starter

Using the old beam style torque wrench, I didn't notice any difference in feel at the correct torque between the side I installed with anti-seize and the side I installed dry. The UCA was stuck in the position I bolted it with both, and wouldn't really move either way. So I went ahead and put anti-seize on both of them and positioned them roughly where I remembered them sitting before removal. With everything back together they seem fine, and move up and down nicely with the wheel. I was just being an idiot and assuming that my arm strength would be comparable to the weight of the car.

#11

Driver School Candidate

The bushings are not bearings. The movement of both upper and lower control arms absorb the rotation by the internal flexing of the rubber. This is why the rubber is bonded to the metal sleeve which locks in place once torqued down. Both control arms should be torqued when the suspension is settled; this way the arm is about center in it's intended travel either up or down. The bushings are not meant to rotate on the bolts, this is most important. Back in the day bronze or brass sleeve bushings were used and had to be lubed with every oil change. The rubber bushings do away with that. If you do not get the arms in the correct position at rest, the bushing will hyper flex and degrade in no time. I am currently replacing also the UCA's and to answer the question; the right side, which is still somewhat stiff, measures exactly 6 inches down from the uppermost part of the fender liner to the center of the arm casting at the center of the ball joint. This is just a rough dimension and I will do the final adjustment by "settling" the suspension. Someone else out there must be able to share the instructions per the LS service manual. Even the lower strut mounting bolt is to be torqued only after settling the suspension. Hard to believe there is significant rotation there, but that's what Lexus specifies.

The following users liked this post:

shouldibuy (03-27-19)

#12

Driver School Candidate

Thread Starter

The bushings are not bearings. The movement of both upper and lower control arms absorb the rotation by the internal flexing of the rubber. This is why the rubber is bonded to the metal sleeve which locks in place once torqued down. Both control arms should be torqued when the suspension is settled; this way the arm is about center in it's intended travel either up or down. The bushings are not meant to rotate on the bolts, this is most important. Back in the day bronze or brass sleeve bushings were used and had to be lubed with every oil change. The rubber bushings do away with that. If you do not get the arms in the correct position at rest, the bushing will hyper flex and degrade in no time. I am currently replacing also the UCA's and to answer the question; the right side, which is still somewhat stiff, measures exactly 6 inches down from the uppermost part of the fender liner to the center of the arm casting at the center of the ball joint. This is just a rough dimension and I will do the final adjustment by "settling" the suspension. Someone else out there must be able to share the instructions per the LS service manual. Even the lower strut mounting bolt is to be torqued only after settling the suspension. Hard to believe there is significant rotation there, but that's what Lexus specifies.

#13

Lexus Champion

Interesting... I did not know the rubber is designed to lock in place to absorb the rotation.

#14

Deduct #3-#2 = resulting distance #4.

Lift the bottom of lower control arm with the scissor jack to match the distance of (#4 + #1).

Once you obtain the right height of lower control arm, you are ready to torque UCA. Without properly torquing UCA and making sure suspension is “reset” towards regular position of wheels on the ground, your suspension may be stiff (as bushings will be in the state of rotation before actual suspension effect), and cause wandering in the highway (if other factors are not impacting this common problem in ls)

Thread

Thread Starter

Forum

Replies

Last Post

wayman28

LS - 4th Gen (2007-2017)

9

09-19-14 02:57 PM