Got an aftermarket Big brake kit and your wheels won’t fit. DYI

#1

Super Moderator

Thread Starter

iTrader: (33)

Join Date: Jul 2004

Location: Sideways on the Yellow Brick Road! < Thats KS!

Posts: 5,827

Likes: 0

Received 4 Likes

on

4 Posts

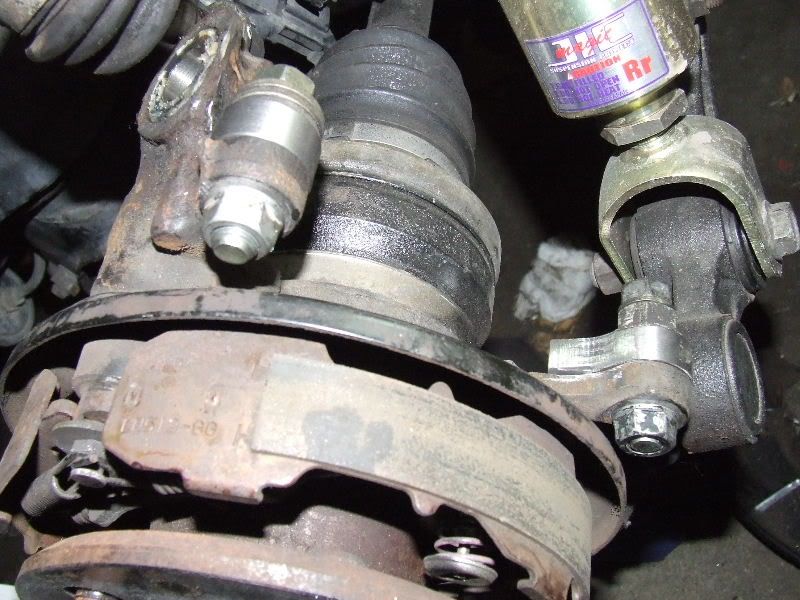

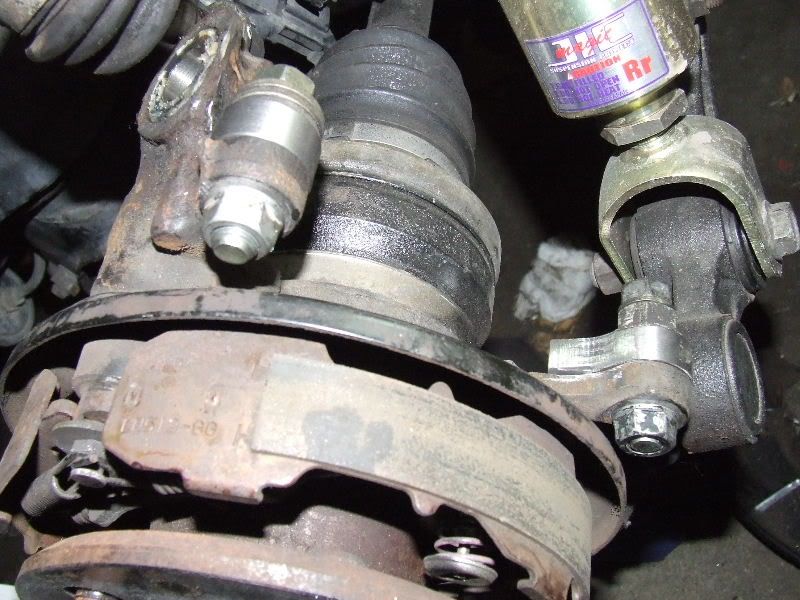

OK, so here is the dilemma. I have the awesome 14” Stoptech Brake set up and it won’t clear my rear wheels. I am really not at all interested in buying a new set of wheels with smaller lips and I can’t stand stretched tires with spacers. Pulling the fenders really is not for me either so what to do. Well I decided if I cant bring the wheels out I really have no choice but to push the brakes back in.

The following is a DIY to move the rear brakes inboard a half inch to allow low disc wheels to fit and retain that big fat lip. This is not a simple deal by any means but I never seem to follow the easy path.

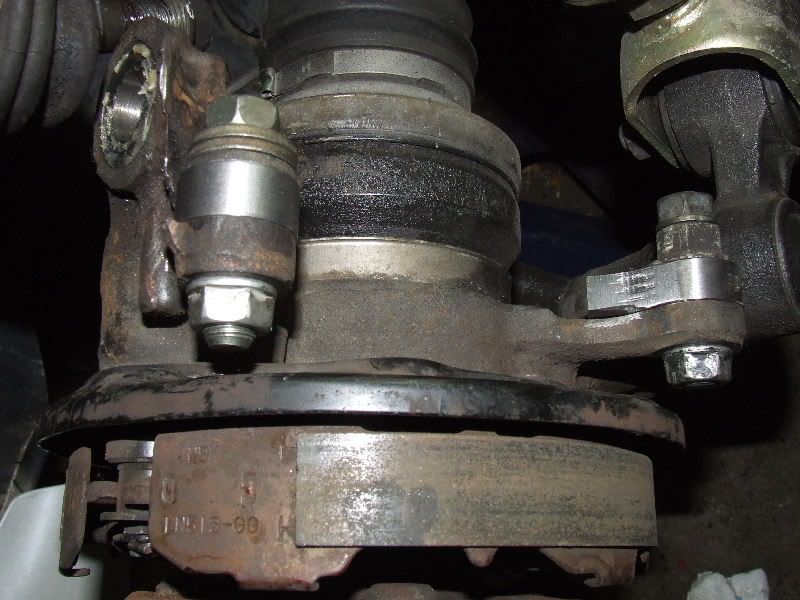

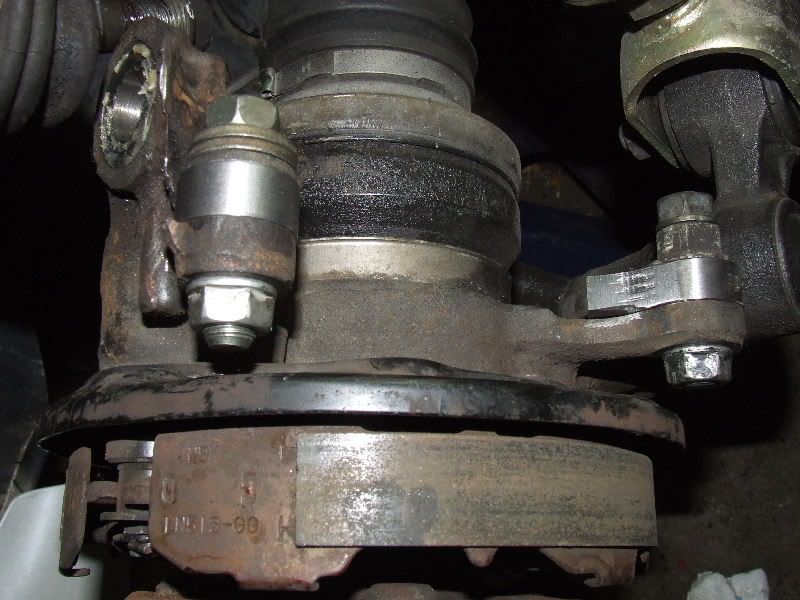

First we have to move the calipers, the only way I see to do this is to physically cut off the caliper mounting ears and weld new ones on further back. The ears are .480” thick so they can be used to fixture the new ears to make sure they get in the exact location needed.

I started by making a set of new ears to replace the ones I will cut off.

Next I bolted them to the backside of the stock ears to hold them in perfect location, this will set them back .480” from the original position, .020” shy of ˝” close enough.

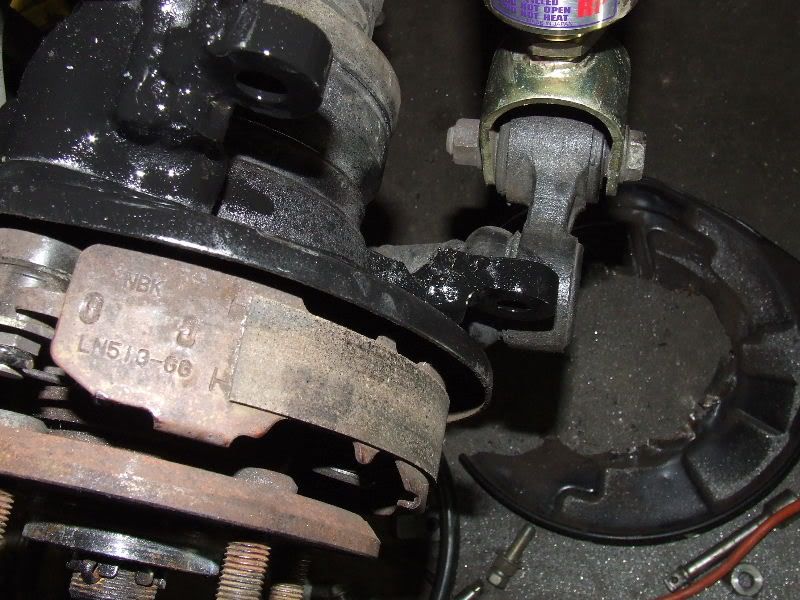

Next they get welded in place, I vee’ed out areas to be welded to allow for better penetration. Carful, don’t weld it to the front ear.

Once they are welded you can cut away the front ear and finish welding them solid, Add paint and wala! New ears to recess the caliper.

The following is a DIY to move the rear brakes inboard a half inch to allow low disc wheels to fit and retain that big fat lip. This is not a simple deal by any means but I never seem to follow the easy path.

First we have to move the calipers, the only way I see to do this is to physically cut off the caliper mounting ears and weld new ones on further back. The ears are .480” thick so they can be used to fixture the new ears to make sure they get in the exact location needed.

I started by making a set of new ears to replace the ones I will cut off.

Next I bolted them to the backside of the stock ears to hold them in perfect location, this will set them back .480” from the original position, .020” shy of ˝” close enough.

Next they get welded in place, I vee’ed out areas to be welded to allow for better penetration. Carful, don’t weld it to the front ear.

Once they are welded you can cut away the front ear and finish welding them solid, Add paint and wala! New ears to recess the caliper.

#2

Super Moderator

Thread Starter

iTrader: (33)

Join Date: Jul 2004

Location: Sideways on the Yellow Brick Road! < Thats KS!

Posts: 5,827

Likes: 0

Received 4 Likes

on

4 Posts

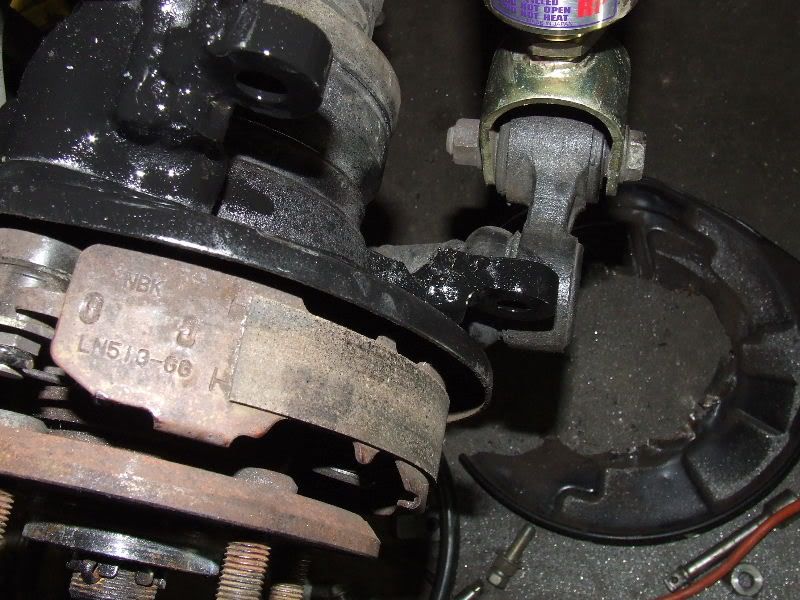

Next up is the rotors, you have to move the braking surface back the same amount the ears moved. Since most aftermarket brakes are two piece floating rotors this can be done.

First take the rotor apart by removing all the allen bolts on the back side. Here is what the parts look like as well as the floating pins.

Next you have to machine a precision spacer, Exact thickness we moved the ears and precision drill it to match the rotor. This piece is a PITA! It must be precision. Took me several hours to whittle 2 of these out of a huge round of aluminum I bought of eBay.

Now, remember the drive pins? Yep, you need 20 custom drive pins, they must be exact length related to stock drive pin plus spacer thickness. If they are too long the rotor will rattle, if they are to short the rotor wont float. The design of these is made as such to just barley extent thru everything stacked up and then a conical spring washer loads it in tension. OH JOY! these are fun to make! NOT! Probably the worst part of it all, after tons of hours, several broken M5 x 80 taps (I don’t think there is another one in town LOL) I have 20 new stainless pins to assemble my rotors.

First take the rotor apart by removing all the allen bolts on the back side. Here is what the parts look like as well as the floating pins.

Next you have to machine a precision spacer, Exact thickness we moved the ears and precision drill it to match the rotor. This piece is a PITA! It must be precision. Took me several hours to whittle 2 of these out of a huge round of aluminum I bought of eBay.

Now, remember the drive pins? Yep, you need 20 custom drive pins, they must be exact length related to stock drive pin plus spacer thickness. If they are too long the rotor will rattle, if they are to short the rotor wont float. The design of these is made as such to just barley extent thru everything stacked up and then a conical spring washer loads it in tension. OH JOY! these are fun to make! NOT! Probably the worst part of it all, after tons of hours, several broken M5 x 80 taps (I don’t think there is another one in town LOL) I have 20 new stainless pins to assemble my rotors.

#3

Super Moderator

Thread Starter

iTrader: (33)

Join Date: Jul 2004

Location: Sideways on the Yellow Brick Road! < Thats KS!

Posts: 5,827

Likes: 0

Received 4 Likes

on

4 Posts

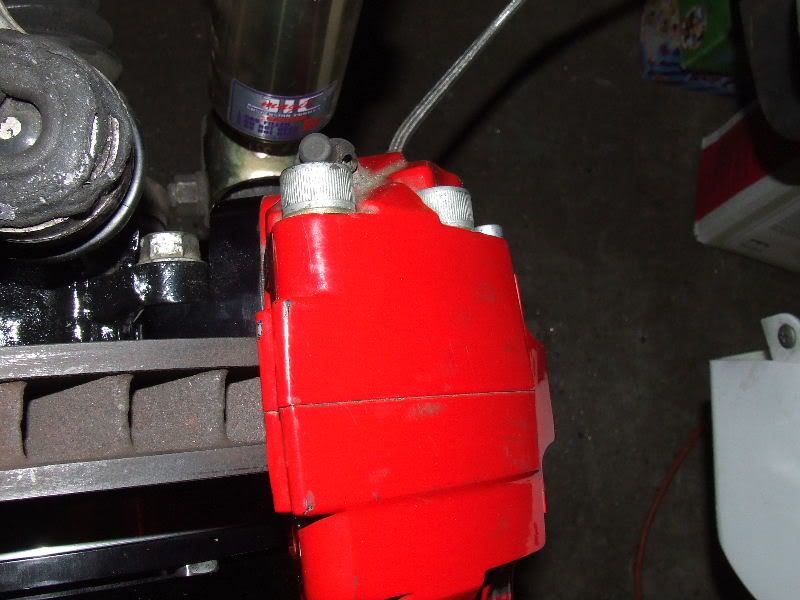

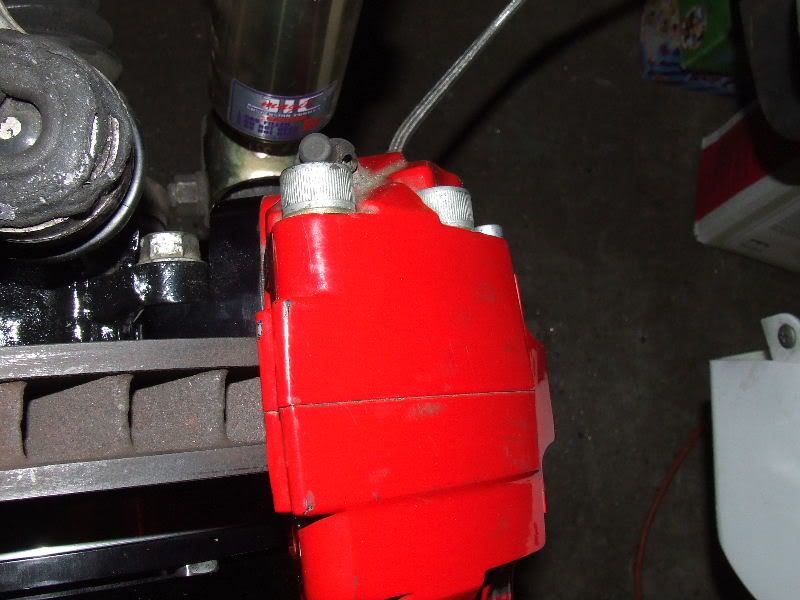

Assembly time!

Last is wheel test fit, Yippee! They fit and have almost .050” clearance, I know, wheels are dirty.

Last how about my 17” Bogart drag wheels, yes I said 17” wheels on 14” brakes. Tons of room!

I must admit this was a ton of work but I have achieved what I set out to do. I now have 14” brakes on all four corners (Overkill I know), No spacers, nice fat lips with a flat center (I don’t like convex wheels) and I can keep my meaty tires in the rear.

Last is wheel test fit, Yippee! They fit and have almost .050” clearance, I know, wheels are dirty.

Last how about my 17” Bogart drag wheels, yes I said 17” wheels on 14” brakes. Tons of room!

I must admit this was a ton of work but I have achieved what I set out to do. I now have 14” brakes on all four corners (Overkill I know), No spacers, nice fat lips with a flat center (I don’t like convex wheels) and I can keep my meaty tires in the rear.

Trending Topics

#10

Super Moderator

Thread Starter

iTrader: (33)

Join Date: Jul 2004

Location: Sideways on the Yellow Brick Road! < Thats KS!

Posts: 5,827

Likes: 0

Received 4 Likes

on

4 Posts

Its just a brake caliper mount ear, Its pletty strong, rear brakes only account for about 30% of the cars stopping force.

Let me throw this at you, There are hundreds of guys on this forum that have swapped in engines and transmissions, many have custom (Cut and welded on) driveshafts, that seems like a more vital component.

I could go on and on with a list of things that people weld on but....................

I guess I have no worries but then again I am a engineer so I think different. LOL

#12

Nice work as always Scott. Your beast continues to be my inspiration, and from one engineer/ CNC machinist to another..... you are golden. Nice ears as well, having access to mills and lathes and the know how to get it done, is always a bonus.

Nice ears as well, having access to mills and lathes and the know how to get it done, is always a bonus.

Nice ears as well, having access to mills and lathes and the know how to get it done, is always a bonus.

Nice ears as well, having access to mills and lathes and the know how to get it done, is always a bonus.

#13

Lead Lap

iTrader: (1)

By "vital component" I simply meant something such as a hub/bearing/braking component.

Yes, other members may have welded driveshafts, made their own seat brackets, etc etc... doesn't mean it was done right. I could weld some *****ty brackets together that will hold until I get into a REAL crash, and they wont have the strength of a precisely machined component, such quality that is obtained from an OEM part. Thats why making modifcations of a truely precise and engineered "component" from Toyota, such as a hub just throws a red-flag in my book.

I wouldn't want to deal with structural integrity concerns... little seed planted in the back of my head whether my caliper ears welds are still holding strong after numerous heat-cycles and hoping there's no imperfections in the welds that might possibly lead to a crack/weak point... But if you dont really drive your car, then no worries, right? I mean, DRIVE. Like time-attack... not car shows and back and forth to work, and the sometimes rare annual drag strip attendance.

Don't get it twisted, I give you much respect for doing your own work and paving a path as opposed to following one. Keep up the individuality.

p.s. someone told me that engineers like to make it known to everyone that they are in fact, an engineer....

Yes, other members may have welded driveshafts, made their own seat brackets, etc etc... doesn't mean it was done right. I could weld some *****ty brackets together that will hold until I get into a REAL crash, and they wont have the strength of a precisely machined component, such quality that is obtained from an OEM part. Thats why making modifcations of a truely precise and engineered "component" from Toyota, such as a hub just throws a red-flag in my book.

I wouldn't want to deal with structural integrity concerns... little seed planted in the back of my head whether my caliper ears welds are still holding strong after numerous heat-cycles and hoping there's no imperfections in the welds that might possibly lead to a crack/weak point... But if you dont really drive your car, then no worries, right? I mean, DRIVE. Like time-attack... not car shows and back and forth to work, and the sometimes rare annual drag strip attendance.

Don't get it twisted, I give you much respect for doing your own work and paving a path as opposed to following one. Keep up the individuality.

p.s. someone told me that engineers like to make it known to everyone that they are in fact, an engineer....

#14

Super Moderator

Thread Starter

iTrader: (33)

Join Date: Jul 2004

Location: Sideways on the Yellow Brick Road! < Thats KS!

Posts: 5,827

Likes: 0

Received 4 Likes

on

4 Posts

By "vital component" I simply meant something such as a hub/bearing/braking component.

Yes, other members may have welded driveshafts, made their own seat brackets, etc etc... doesn't mean it was done right. I could weld some *****ty brackets together that will hold until I get into a REAL crash, and they wont have the strength of a precisely machined component, such quality that is obtained from an OEM part. Thats why making modifcations of a truely precise and engineered "component" from Toyota, such as a hub just throws a red-flag in my book.

I wouldn't want to deal with structural integrity concerns... little seed planted in the back of my head whether my caliper ears welds are still holding strong after numerous heat-cycles and hoping there's no imperfections in the welds that might possibly lead to a crack/weak point... But if you dont really drive your car, then no worries, right? I mean, DRIVE. Like time-attack... not car shows and back and forth to work, and the sometimes rare annual drag strip attendance.

Don't get it twisted, I give you much respect for doing your own work and paving a path as opposed to following one. Keep up the individuality.

Yes, other members may have welded driveshafts, made their own seat brackets, etc etc... doesn't mean it was done right. I could weld some *****ty brackets together that will hold until I get into a REAL crash, and they wont have the strength of a precisely machined component, such quality that is obtained from an OEM part. Thats why making modifcations of a truely precise and engineered "component" from Toyota, such as a hub just throws a red-flag in my book.

I wouldn't want to deal with structural integrity concerns... little seed planted in the back of my head whether my caliper ears welds are still holding strong after numerous heat-cycles and hoping there's no imperfections in the welds that might possibly lead to a crack/weak point... But if you dont really drive your car, then no worries, right? I mean, DRIVE. Like time-attack... not car shows and back and forth to work, and the sometimes rare annual drag strip attendance.

Don't get it twisted, I give you much respect for doing your own work and paving a path as opposed to following one. Keep up the individuality.

Yep, I understand totally, if the welds are bad there is no doubt they would break, I feel pretty good about my own work and at the end of the day I guess I am the one that has to live with it. If it were holding on a wheel I might be a little more worried but then again I have welded together complete Dune Buggies punished the crap out of them by jumping them over dunes entrusting my life to their cage and testing it from time to time.

Thanks for your feedback and I take it into consideration. You make some great points for sure.

BTW, I loved the hidden note.

p.s. I laughed at you PS note. We all have to be something, its not always what we want.

Last edited by ScottURnot; 04-05-10 at 08:51 PM.