Timing belt change nightmare

#16

Driver School Candidate

Join Date: Apr 2007

Location: ca

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

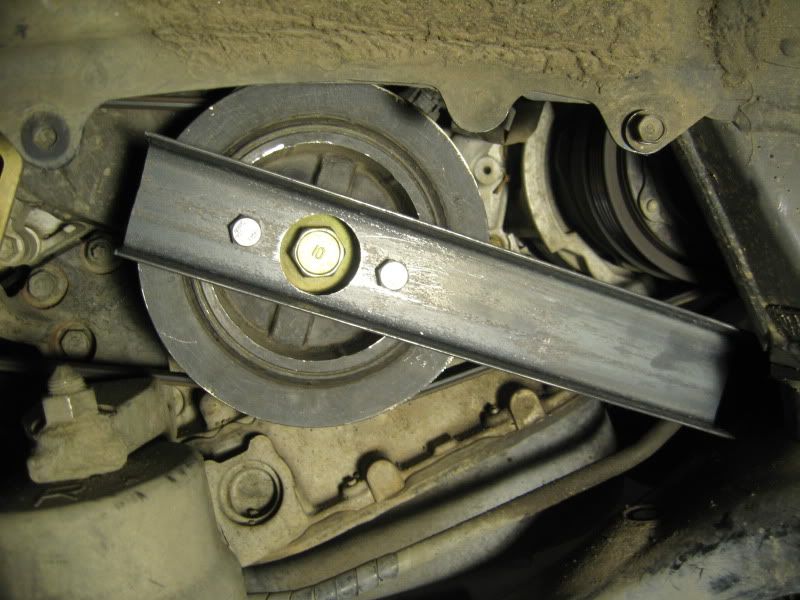

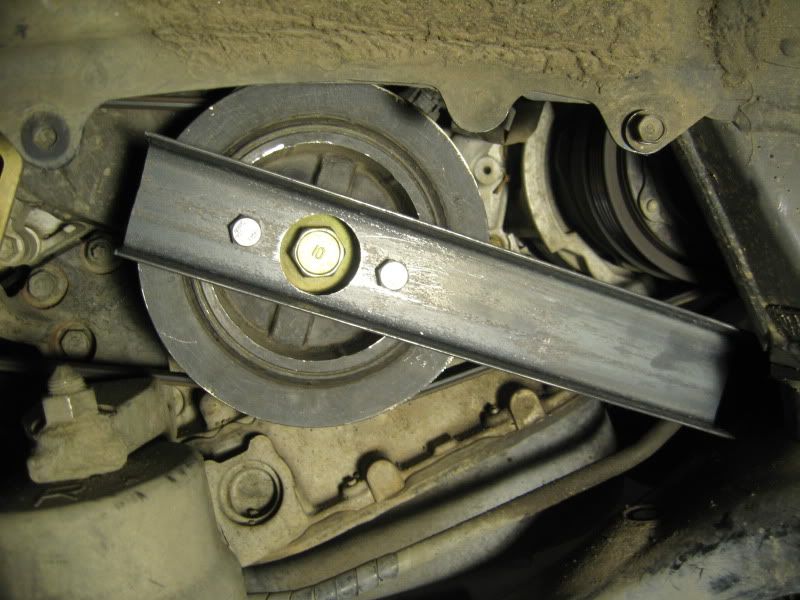

SST took about thirty minutes to get materials at Ace Hardware & make. Please excuse the detail but it may help others too?

I. Channel beam (in metal bin, about 2" wide X 24" long X 1/4" thick). If this breaks, will just buy thicker beam and make another (was on motorcycle so took biggest one that would fit in backpack ha ha);

II. Cut beam about 11.5" long with portable half dead batteried Makita reciprocating saw;

[Some measurements taken with caliper on mm setting.]

III. Etch center line across length of beam. Start first hole for crank pulley "hold bolts" at 48mm from one end of beam, then drill second hole 66mm apart from first hole (forget what size drill bit, but "hold hole bolts" are metric 8X1.25 thread X 45.55mm long, Grade 8 or higher)...

Backed up hold bolts with about 15 (or so???) washers, flush against crank pulley (can't see washers in picture because they're on hold bolts behind beam, inside crank pulley recess);

IV. "Pulley Bolt" socket access hole centered at 33mm between hold bolt holes, drilled with 1 3/8" hole saw... Ace Hardware #24312 & Ace 1/4" Pilot Bit #24331...

This center hole accommodates a 22mm socket to break pulley bolt free. Pic shows it in "tighten" position (wanted to be sure it'd work both ways before removing bolt). Swap sides to loosen/ tighten, braced against suspension either way.

A good impact gun works but don't like idea of hammering these parts on my beautiful RX.

Schley makes harmonic balancer holding tool for $50 - $90, but this home made thing was quick & easy to make for $20, didn't have to wait for shipping and have a little extra beach/ concert/ fun money...

Pix of some raw materials left over...

Pix of 1/4 - 3/8 - 1/2" drive Snapon digi torque wrenches set at highest NM settings...

Hope this helps!

I. Channel beam (in metal bin, about 2" wide X 24" long X 1/4" thick). If this breaks, will just buy thicker beam and make another (was on motorcycle so took biggest one that would fit in backpack ha ha);

II. Cut beam about 11.5" long with portable half dead batteried Makita reciprocating saw;

[Some measurements taken with caliper on mm setting.]

III. Etch center line across length of beam. Start first hole for crank pulley "hold bolts" at 48mm from one end of beam, then drill second hole 66mm apart from first hole (forget what size drill bit, but "hold hole bolts" are metric 8X1.25 thread X 45.55mm long, Grade 8 or higher)...

Backed up hold bolts with about 15 (or so???) washers, flush against crank pulley (can't see washers in picture because they're on hold bolts behind beam, inside crank pulley recess);

IV. "Pulley Bolt" socket access hole centered at 33mm between hold bolt holes, drilled with 1 3/8" hole saw... Ace Hardware #24312 & Ace 1/4" Pilot Bit #24331...

This center hole accommodates a 22mm socket to break pulley bolt free. Pic shows it in "tighten" position (wanted to be sure it'd work both ways before removing bolt). Swap sides to loosen/ tighten, braced against suspension either way.

A good impact gun works but don't like idea of hammering these parts on my beautiful RX.

Schley makes harmonic balancer holding tool for $50 - $90, but this home made thing was quick & easy to make for $20, didn't have to wait for shipping and have a little extra beach/ concert/ fun money...

Pix of some raw materials left over...

Pix of 1/4 - 3/8 - 1/2" drive Snapon digi torque wrenches set at highest NM settings...

Hope this helps!

#17

Moderator

Brilliant!

Brilliant!

Salim

#18

#20

Moderator

Time for me to buy a new tool ... need a TR that goes upto 200 lb-ft

Salim

Salim

#21

Pole Position

I can put in a favorable word for the Schley tool referenced in post #17 (the crank pulley holder). Besides being useful for removing the crank pulley retaining bolt it also gives you the ability to use a breakover bar or ratchet to position the crank to the correct position for installing the timing belt. You can also use it for manually turning the crank through a couple rotations when the new timing belt is in place. The one I bought was $60 all-in from Amazon a little over a year ago. At the time I had three Toyota products with timing belts so it was easy to justify the purchase.

#22

Driver School Candidate

Join Date: Apr 2007

Location: ca

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Thanks S... easily made grunt tool!

The ATECH T.W.'s read in Newton Meters, Inch & Foot Pounds, and Angle (in degrees). Thought doing preventive maintenance myself would offset the cost of having good tools (useful for other projects).

Conversely, once saw a guy at Pep Boys on Hollywood Bl. ruin a brand new $150 battery with a new $15 tool kit so it could really go both ways for anyone. It's just nice to have good help (and to know) when needed!

Like the Schley line. Just ordered their valve shim removal tool, should be here this week. Touchy stuff.

Have a great day!

The ATECH T.W.'s read in Newton Meters, Inch & Foot Pounds, and Angle (in degrees). Thought doing preventive maintenance myself would offset the cost of having good tools (useful for other projects).

Conversely, once saw a guy at Pep Boys on Hollywood Bl. ruin a brand new $150 battery with a new $15 tool kit so it could really go both ways for anyone. It's just nice to have good help (and to know) when needed!

Like the Schley line. Just ordered their valve shim removal tool, should be here this week. Touchy stuff.

Have a great day!

Last edited by luvrxxx; 08-24-11 at 01:18 PM.

#23

Driver School Candidate

RE: Post #16 - the home made tool as shown would make loosening the crank bolt possible, i would guess, but how about pulling the crank out after the bolt is removed? is it fairly easy or would a puller still needed?

#24

Driver School Candidate

Join Date: Apr 2007

Location: ca

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Off topic, also bought an "OEM" brand digital inch/ mm caliper which is identical to Snapon/ Bluepoint.

Hope this helps!

#25

Driver School Candidate

Pep Boys has an "OEM" brand puller that works for around $30 (not claw type, but bolts into two "side" bolt holes on harmonic balancer & turns at center). Keep center threads greased. Didn't come with case but is decent quality with "lifetime" warranty.

Off topic, also bought an "OEM" brand digital inch/ mm caliper which is identical to Snapon/ Bluepoint.

Hope this helps!

Off topic, also bought an "OEM" brand digital inch/ mm caliper which is identical to Snapon/ Bluepoint.

Hope this helps!

#26

Driver School Candidate

Join Date: Apr 2007

Location: ca

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

The caliper's OEM 25363, used to accurately measure things like valve shims on bikes & cars (may come in handy on the RX if can't read shims that need to be changed), harmonic balancer "hold bolt hole" distance for "SST", etc.

Hope this helps!

#27

Moderator

Salim

#29

Pole Position

SST took about thirty minutes to get materials at Ace Hardware & make. Please excuse the detail but it may help others too?

I. Channel beam (in metal bin, about 2" wide X 24" long X 1/4" thick). If this breaks, will just buy thicker beam and make another (was on motorcycle so took biggest one that would fit in backpack ha ha);

II. Cut beam about 11.5" long with portable half dead batteried Makita reciprocating saw;

[Some measurements taken with caliper on mm setting.]

III. Etch center line across length of beam. Start first hole for crank pulley "hold bolts" at 48mm from one end of beam, then drill second hole 66mm apart from first hole (forget what size drill bit, but "hold hole bolts" are metric 8X1.25 thread X 45.55mm long, Grade 8 or higher)...

Backed up hold bolts with about 15 (or so???) washers, flush against crank pulley (can't see washers in picture because they're on hold bolts behind beam, inside crank pulley recess);

IV. "Pulley Bolt" socket access hole centered at 33mm between hold bolt holes, drilled with 1 3/8" hole saw... Ace Hardware #24312 & Ace 1/4" Pilot Bit #24331...

This center hole accommodates a 22mm socket to break pulley bolt free. Pic shows it in "tighten" position (wanted to be sure it'd work both ways before removing bolt). Swap sides to loosen/ tighten, braced against suspension either way.

A good impact gun works but don't like idea of hammering these parts on my beautiful RX.

Schley makes harmonic balancer holding tool for $50 - $90, but this home made thing was quick & easy to make for $20, didn't have to wait for shipping and have a little extra beach/ concert/ fun money...

Pix of some raw materials left over...

Pix of 1/4 - 3/8 - 1/2" drive Snapon digi torque wrenches set at highest NM settings...

Hope this helps!

I. Channel beam (in metal bin, about 2" wide X 24" long X 1/4" thick). If this breaks, will just buy thicker beam and make another (was on motorcycle so took biggest one that would fit in backpack ha ha);

II. Cut beam about 11.5" long with portable half dead batteried Makita reciprocating saw;

[Some measurements taken with caliper on mm setting.]

III. Etch center line across length of beam. Start first hole for crank pulley "hold bolts" at 48mm from one end of beam, then drill second hole 66mm apart from first hole (forget what size drill bit, but "hold hole bolts" are metric 8X1.25 thread X 45.55mm long, Grade 8 or higher)...

Backed up hold bolts with about 15 (or so???) washers, flush against crank pulley (can't see washers in picture because they're on hold bolts behind beam, inside crank pulley recess);

IV. "Pulley Bolt" socket access hole centered at 33mm between hold bolt holes, drilled with 1 3/8" hole saw... Ace Hardware #24312 & Ace 1/4" Pilot Bit #24331...

This center hole accommodates a 22mm socket to break pulley bolt free. Pic shows it in "tighten" position (wanted to be sure it'd work both ways before removing bolt). Swap sides to loosen/ tighten, braced against suspension either way.

A good impact gun works but don't like idea of hammering these parts on my beautiful RX.

Schley makes harmonic balancer holding tool for $50 - $90, but this home made thing was quick & easy to make for $20, didn't have to wait for shipping and have a little extra beach/ concert/ fun money...

Pix of some raw materials left over...

Pix of 1/4 - 3/8 - 1/2" drive Snapon digi torque wrenches set at highest NM settings...

Hope this helps!

#30

Pole Position