Boosting with the twins... is250 turbo build

#151

It definitely looks like it's coming past the seals. You've verified that you're only running 35-40 psi oil pressure to the turbos correct?

What does the oil in tank look like. It looks like you've got water contamination. As the oil heats and cools moisture/condensation will build up. With the small amount of oil in that system it could quickly contaminate it.

Adding a vent may be beneficial or possibly changing the container or amount of oil so that the fluid level stays pretty high.

I'll do some digging...

What does the oil in tank look like. It looks like you've got water contamination. As the oil heats and cools moisture/condensation will build up. With the small amount of oil in that system it could quickly contaminate it.

Adding a vent may be beneficial or possibly changing the container or amount of oil so that the fluid level stays pretty high.

I'll do some digging...

#152

The oil in the tank is still honey colored and uncontaminated. Not sure how I would be able to confirm that there is exactly 35-40 psi in the oil system. Is there anyway to tell if I blew the oil seals in the turbo? They seem to spin freely without any noises or scratching in the turbo walls. I know for sure that upon start up every time the car would throw a bit of water from the exhaust tips. Maybe that's what's mixing with the oil that's blowing past the seals?

#153

Milkshake=oil+water. You get the same result when a headgasket blows and the oil/water mixes.

I still think the angle you have the oil drain isn't good and there is obviously a few problems with the turbo oiling system feeding the turbos or the drain-back setup.

How much in-and-out play is there in the shaft? Not side-to-side; push the shaft in and pull towards yourself. Ideally (with oil in it) you should not have any; even with oil, you should expect some side-to-side play with the shaft.

Can you draw up a crude MS Paint of how exactly you've got your turbo oiling system designed?

I still think the angle you have the oil drain isn't good and there is obviously a few problems with the turbo oiling system feeding the turbos or the drain-back setup.

How much in-and-out play is there in the shaft? Not side-to-side; push the shaft in and pull towards yourself. Ideally (with oil in it) you should not have any; even with oil, you should expect some side-to-side play with the shaft.

Can you draw up a crude MS Paint of how exactly you've got your turbo oiling system designed?

#154

Once the oil has made it past the seals of the turbo it's not likely to make it's way back as the oil inside the turbo is pressurized so I don't think condensation in the exhaust is causing your issues.

#155

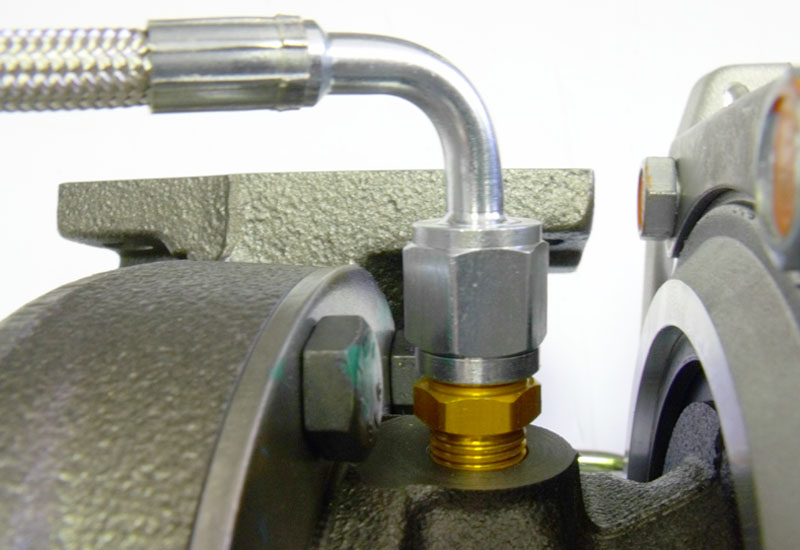

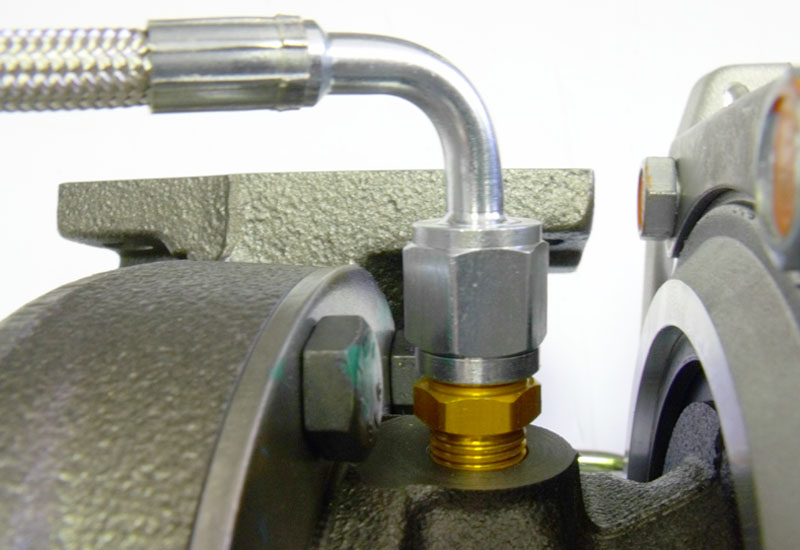

This is the video and pic that leads me to believe that you haven't clocked the turbos (or at least this one) correctly; even remote turbo setups with unique oiling systems need a typical oil inlet and outlet. That being closest to perfectly straight up/down :

Here's an example from a WELL-KNOWN remote turbo company (STS); and I'd trust anything they'd do :

Here's an example from a WELL-KNOWN remote turbo company (STS); and I'd trust anything they'd do :

The following users liked this post:

214iscLyfe (12-29-19)

#159

Driver School Candidate

You pick up parts like groceries man! Haha. So it was potentially just factory defective turbo? (assuming it was the seals that were pooched). You also have it back in the same position as it was previous in regards to the clocking - feed and return being on an angle and all?

The following users liked this post:

214iscLyfe (12-29-19)

#160

You pick up parts like groceries man! Haha. So it was potentially just factory defective turbo? (assuming it was the seals that were pooched). You also have it back in the same position as it was previous in regards to the clocking - feed and return being on an angle and all?

Oil inlet and outlet are still in the same position as you stated.

#161

Hope these new turbos work out better for you.

Still would like to see some details on how exactly you plumed the oiling system.

#163

Driver School Candidate

Sounds like that could have been a contributing factor to the issue. overfilling oil in the engine itself can cause the crank to whip the oil into a nice creamy like state so maybe the presence of too much oil with the heat of the turbo and access within the housing could have caused that milky like substance rather than condensation in the exhaust. Potentially no?

Essentially the turbos work a little harder being rear mount, and since they're obviously smaller turbos an oil cooler is probably a good idea to. By the way you're tackling this, I'm sure you've already looked into that lol.

I might play copycat in the spring when I pick up a new vehicle and try mimicking your whole design. It's sick that you're doing this and sharing it all with us. A big thank you man!

Essentially the turbos work a little harder being rear mount, and since they're obviously smaller turbos an oil cooler is probably a good idea to. By the way you're tackling this, I'm sure you've already looked into that lol.

I might play copycat in the spring when I pick up a new vehicle and try mimicking your whole design. It's sick that you're doing this and sharing it all with us. A big thank you man!

Last edited by medic250; 12-27-13 at 10:31 PM. Reason: Edit

#164

So the tank holds the 2 qts of oil (mobile1 5-30), it's fed into the turbos by a marine pump and it's fed back into the tank by another marine pump.

Still haven't been able to find a local shop that can make me custom stainless steel braided lines so I'm running rubber for now.

#165

So yeah, trust the oil restrictors; the turbos don't need that much oil flow. Here's an example of an oil feed line that fed my much larger turbo I had for my boosted Civic :

The return should be double/triple the size of the feed line. I'm concerned on how exactly you've got the turbo's oiling system setup that you're feeding one turbo with oil from the tank, then that hot oil travels to the second turbo to get even hotter and then returns into the tank. No cooling, no in-line filtration...not good.

Is there a specific setup out there that you took your ideas from? Got links to it?

The return should be double/triple the size of the feed line. I'm concerned on how exactly you've got the turbo's oiling system setup that you're feeding one turbo with oil from the tank, then that hot oil travels to the second turbo to get even hotter and then returns into the tank. No cooling, no in-line filtration...not good.

Is there a specific setup out there that you took your ideas from? Got links to it?