Engine torque dampers

#1

Lexus Champion

Thread Starter

ClubLexus forum members report LS400 motor mounts are prone to seperation from more than a few full-throttle uses of accelerator pedal...

Mercedez uses engine torque dampers to alleviate the problem or the motor mounts being wrenched at rapid throttle actuation.

Attached are images and a link to the relevant article...

https://www.fcpeuro.com/blog/posts/mercedes-engine-torque-dampers-shocks

"The engine shocks or torque dampers are literally small shock absorbers for the engine. These shocks or torque dampers keep the engine from rotating or twisting when it is put under heavy load through acceleration.

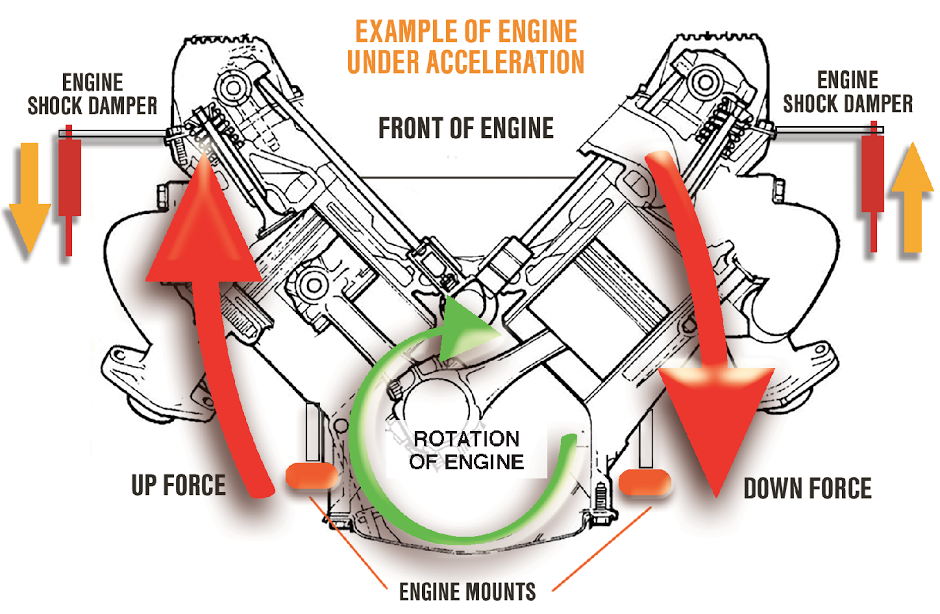

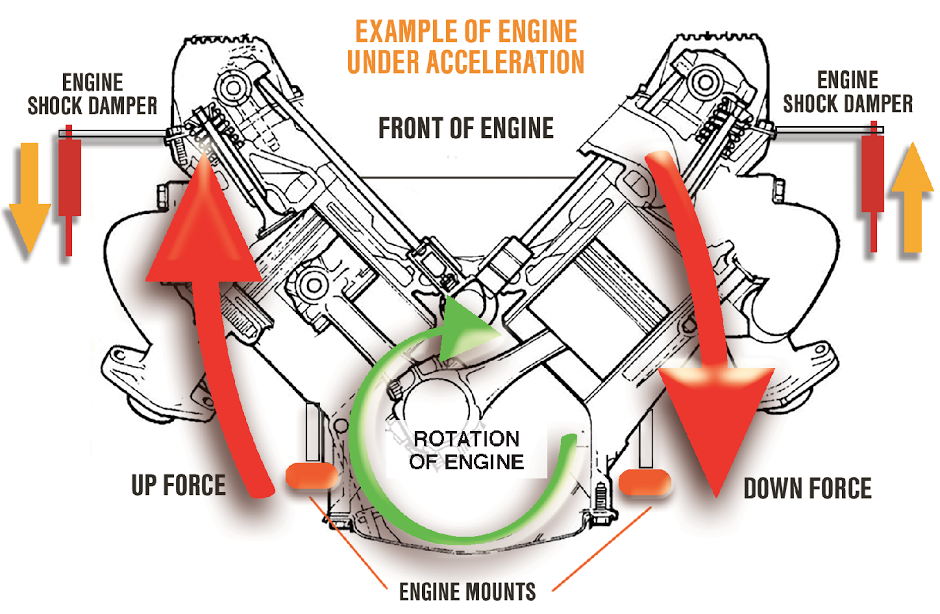

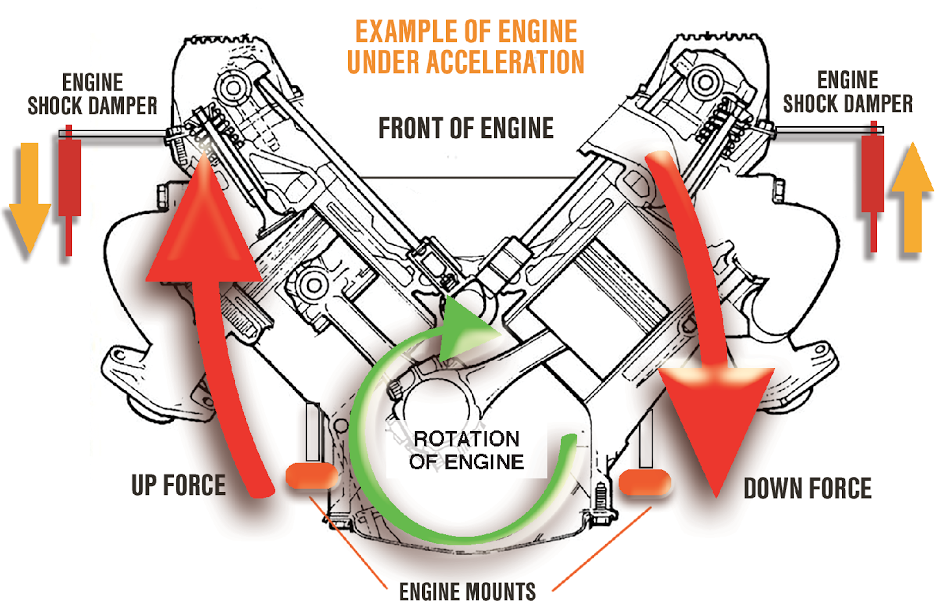

The diagram shows an example of how an engine responds when under acceleration.The engine shocks are readily available and should be replaced in the event they are original or have failed. It should be noted that Mercedes varied the location of the dampers on the 450SL over time. A number of models had the torque dampers mounted down lower while the 1975 450SL had them mounted in the general location of the rendering above. In as much, the 450SL engine shock dampers that are available, vary in size as do the necessary mounting hardware kits that vary slightly in design and fitment. Always be sure to confirm you chassis number and whether or not your version is a California or Federal model.

While the engine dampers are generally under little strain, they do kick into action under very hard acceleration. As the engine “rotates”, the engine wants to lift up on one side hence “pressing” down on the other. The dampers control that twisting/lifting motion just as the road shocks control the up and down movement of the wheels.

The engine shocks in my 1975 450SL appear to be original and had no ability to control the engine torque any longer. While it may not seem necessary to replace them, unlike engine mounts (right or left), the damper does control very unwanted movement of the engine and attached transmission. The constant “twisting” of the engine with out functioning engine torque dampers puts undue strain on the engine and transmission mounts and reduces the overall comfort of ones overall driving experience. NOTE: The engine shock dampers do not replace the engine mounts which serve to control vibration, not twisting movement.

We will cover the installation of the engine shock damper for the 1975 450SL only. As mentioned earlier, Mercedes relocated the engine shock dampers several times over various chassis. Each variant has specific instructions for removal and install."

Has anyone on this forum worked on a similar solution for Lexus or familiar with a source?

#2

Lexus Champion

Thread Starter

ClubLexus forum members report LS400 motor mounts are prone to seperation from more than a few full-throttle uses of accelerator pedal...

Mercedez uses engine torque dampers to alleviate the problem or the motor mounts being wrenched at rapid throttle actuation.

Attached are images and a link to the relevant article...

https://www.fcpeuro.com/blog/posts/mercedes-engine-torque-dampers-shocks

"The engine shocks or torque dampers are literally small shock absorbers for the engine. These shocks or torque dampers keep the engine from rotating or twisting when it is put under heavy load through acceleration.

The diagram shows an example of how an engine responds when under acceleration.The engine shocks are readily available and should be replaced in the event they are original or have failed. It should be noted that Mercedes varied the location of the dampers on the 450SL over time. A number of models had the torque dampers mounted down lower while the 1975 450SL had them mounted in the general location of the rendering above. In as much, the 450SL engine shock dampers that are available, vary in size as do the necessary mounting hardware kits that vary slightly in design and fitment. Always be sure to confirm you chassis number and whether or not your version is a California or Federal model.

While the engine dampers are generally under little strain, they do kick into action under very hard acceleration. As the engine “rotates”, the engine wants to lift up on one side hence “pressing” down on the other. The dampers control that twisting/lifting motion just as the road shocks control the up and down movement of the wheels.

The engine shocks in my 1975 450SL appear to be original and had no ability to control the engine torque any longer. While it may not seem necessary to replace them, unlike engine mounts (right or left), the damper does control very unwanted movement of the engine and attached transmission. The constant “twisting” of the engine with out functioning engine torque dampers puts undue strain on the engine and transmission mounts and reduces the overall comfort of ones overall driving experience. NOTE: The engine shock dampers do not replace the engine mounts which serve to control vibration, not twisting movement.

We will cover the installation of the engine shock damper for the 1975 450SL only. As mentioned earlier, Mercedes relocated the engine shock dampers several times over various chassis. Each variant has specific instructions for removal and install."

Has anyone on this forum worked on a similar solution for Lexus or familiar with a source?

Administrator.. Please move to new postings...

#3

Lexus Champion

Thread Starter

ClubLexus forum members report LS400 motor mounts are prone to seperation after a few full-throttle bursts of accelerator pedal...

Mercedez uses engine torque dampers to alleviate the problem or the motor mounts being wrenched by engine torque under acceleration and especially during rapid throttle actuation

Attached are images and a link to the relevant article...

https://www.fcpeuro.com/blog/posts/mercedes-engine-torque-dampers-shocks

"The engine shocks or torque dampers are literally small shock absorbers for the engine. These shocks or torque dampers keep the engine from rotating or twisting when it is put under heavy load through acceleration.

The diagram shows an example of how an engine responds when under acceleration.The engine shocks are readily available and should be replaced in the event they are original or have failed. It should be noted that Mercedes varied the location of the dampers on the 450SL over time. A number of models had the torque dampers mounted down lower while the 1975 450SL had them mounted in the general location of the rendering above. In as much, the 450SL engine shock dampers that are available, vary in size as do the necessary mounting hardware kits that vary slightly in design and fitment. Always be sure to confirm you chassis number and whether or not your version is a California or Federal model.

While the engine dampers are generally under little strain, they do kick into action under very hard acceleration. As the engine “rotates”, the engine wants to lift up on one side hence “pressing” down on the other. The dampers control that twisting/lifting motion just as the road shocks control the up and down movement of the wheels.

The engine shocks in my 1975 450SL appear to be original and had no ability to control the engine torque any longer. While it may not seem necessary to replace them, unlike engine mounts (right or left), the damper does control very unwanted movement of the engine and attached transmission. The constant “twisting” of the engine with out functioning engine torque dampers puts undue strain on the engine and transmission mounts and reduces the overall comfort of ones overall driving experience. NOTE: The engine shock dampers do not replace the engine mounts which serve to control vibration, not twisting movement.

We will cover the installation of the engine shock damper for the 1975 450SL only. As mentioned earlier, Mercedes relocated the engine shock dampers several times over various chassis. Each variant has specific instructions for removal and install."

Has anyone worked a solution to this problem?

My thought is the strut tower mounting studs could be used to affix left and right body-side damper mounts and possibly the power steering mounting bolts on the right side of engine(slightly longer bolts available from McMaster-Carr Supply...used them to obtain correct replacement fasteners when replacing P.S. pump because discontinued by Lexus)

) and the AC Compressor mounting bolts on the left side...or some other mounting configuration.

This image depicts how torque shifts the engine each time the accelerator pedal is depressed..

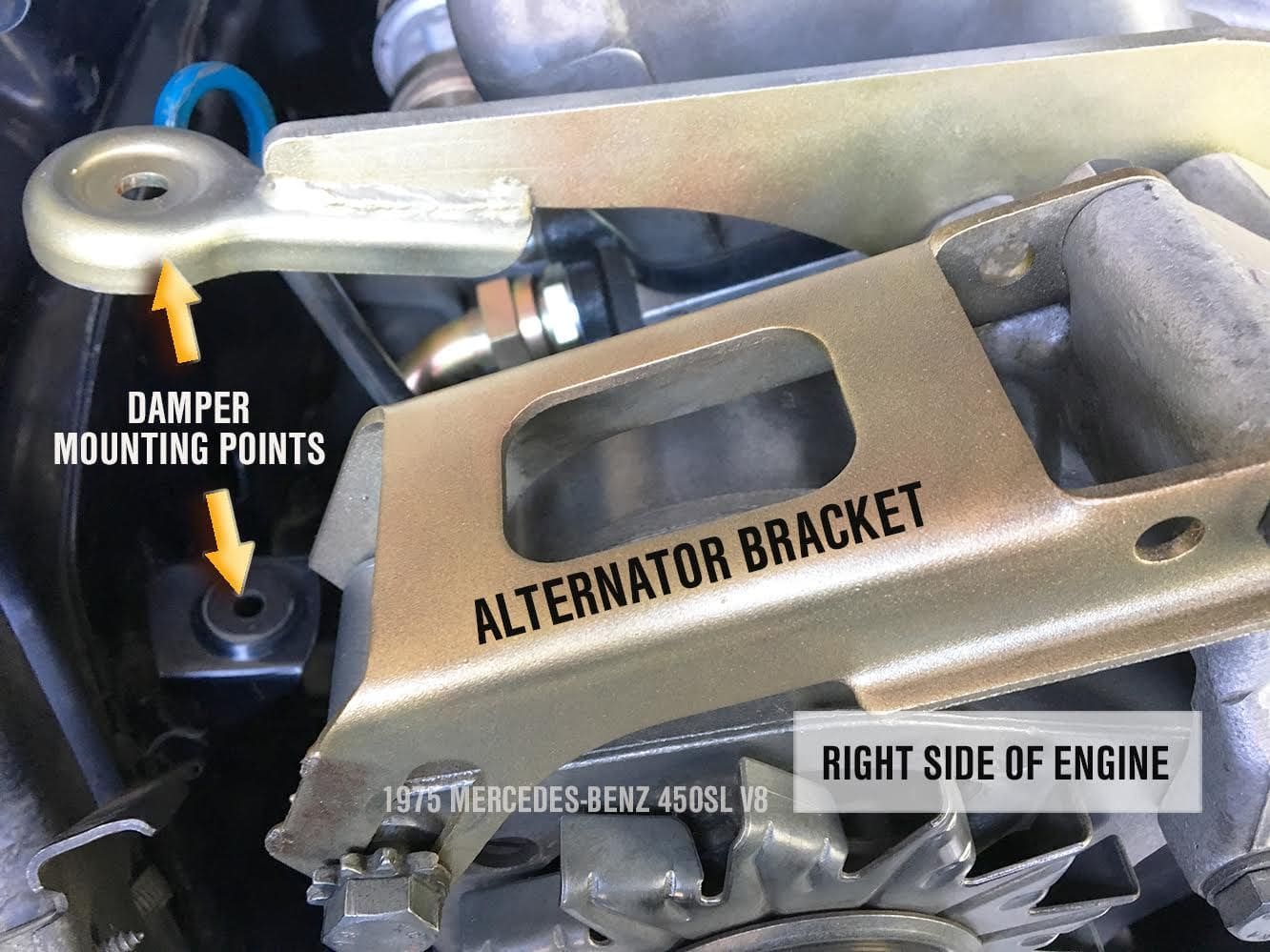

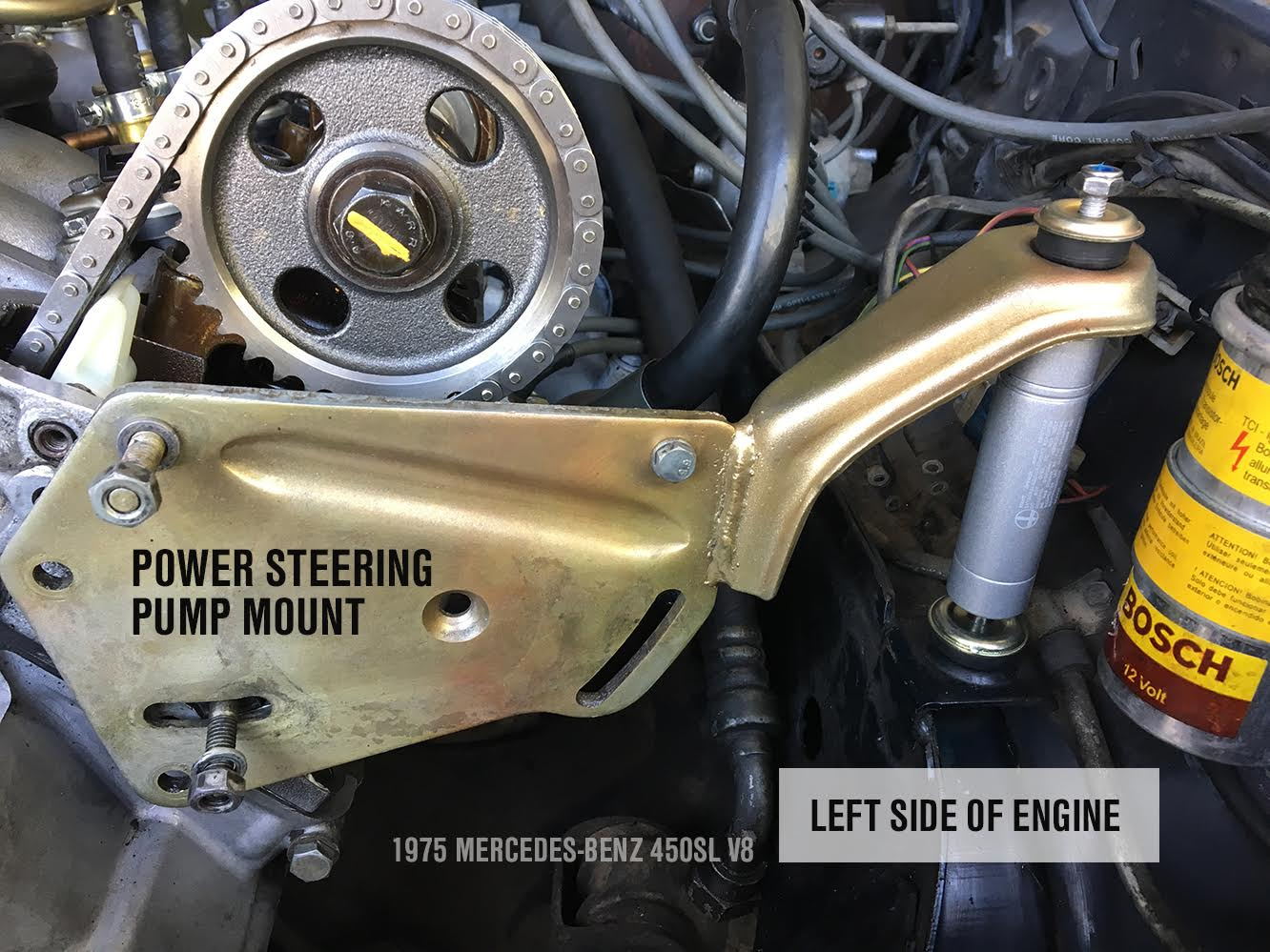

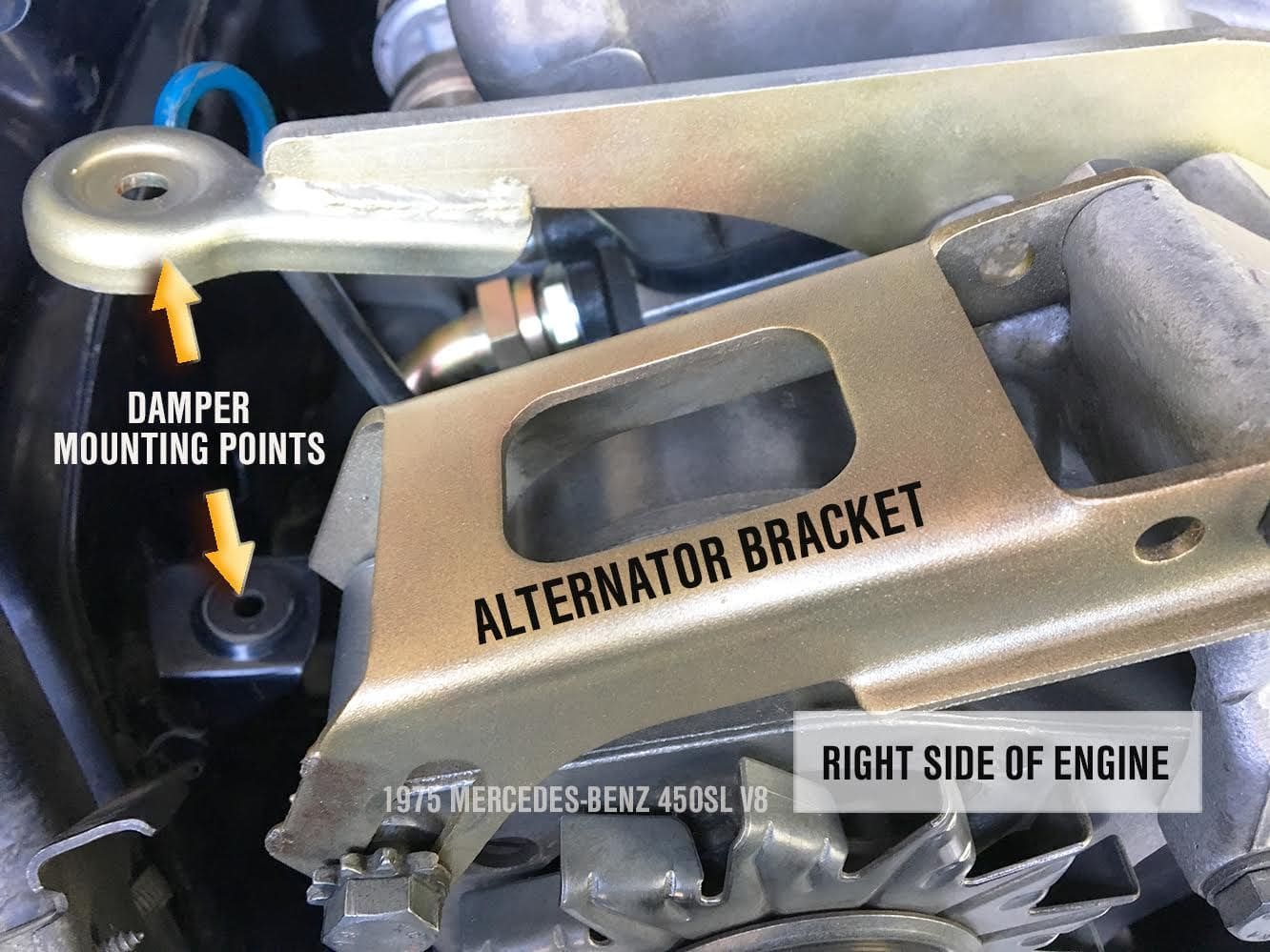

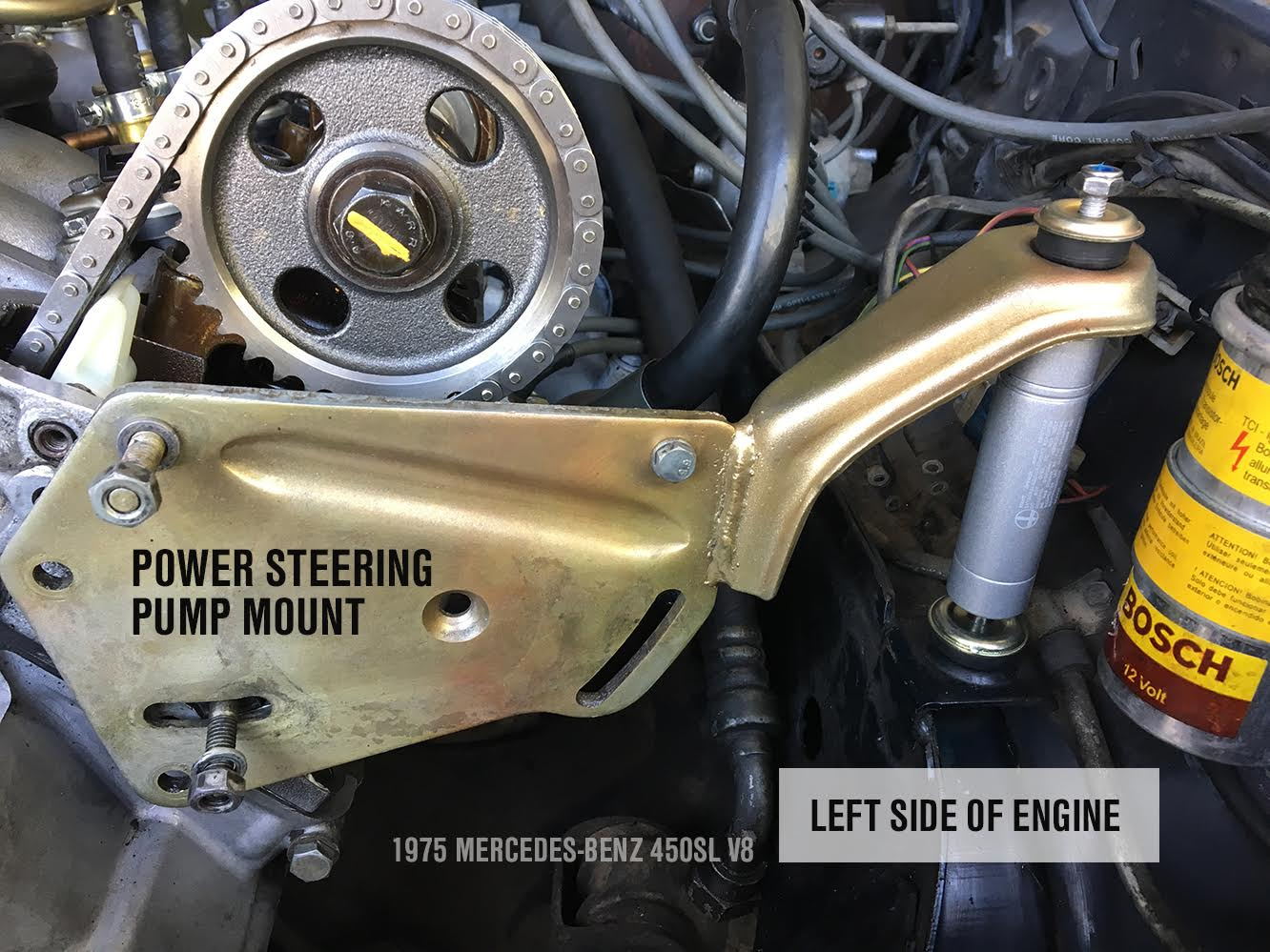

This image depicts how Mercedes Benz torque damper is mounted

on left side....

.....

Mercedes-Benz torque dampers resemble miniature shock absorbers....The O.EM..Lexus mounts are well designed for isolation but have their design limitations when it comes to controlling engine movement.

Mercedez uses engine torque dampers to alleviate the problem or the motor mounts being wrenched at rapid throttle actuation.

Attached are images and a link to the relevant article...

https://www.fcpeuro.com/blog/posts/mercedes-engine-torque-dampers-shocks

"The engine shocks or torque dampers are literally small shock absorbers for the engine. These shocks or torque dampers keep the engine from rotating or twisting when it is put under heavy load through acceleration.

The diagram shows an example of how an engine responds when under acceleration.The engine shocks are readily available and should be replaced in the event they are original or have failed. It should be noted that Mercedes varied the location of the dampers on the 450SL over time. A number of models had the torque dampers mounted down lower while the 1975 450SL had them mounted in the general location of the rendering above. In as much, the 450SL engine shock dampers that are available, vary in size as do the necessary mounting hardware kits that vary slightly in design and fitment. Always be sure to confirm you chassis number and whether or not your version is a California or Federal model.

While the engine dampers are generally under little strain, they do kick into action under very hard acceleration. As the engine “rotates”, the engine wants to lift up on one side hence “pressing” down on the other. The dampers control that twisting/lifting motion just as the road shocks control the up and down movement of the wheels.

The engine shocks in my 1975 450SL appear to be original and had no ability to control the engine torque any longer. While it may not seem necessary to replace them, unlike engine mounts (right or left), the damper does control very unwanted movement of the engine and attached transmission. The constant “twisting” of the engine with out functioning engine torque dampers puts undue strain on the engine and transmission mounts and reduces the overall comfort of ones overall driving experience. NOTE: The engine shock dampers do not replace the engine mounts which serve to control vibration, not twisting movement.

We will cover the installation of the engine shock damper for the 1975 450SL only. As mentioned earlier, Mercedes relocated the engine shock dampers several times over various chassis. Each variant has specific instructions for removal and install."roling (think of a car with springs and no , or worn, shock absorbers) sudden engine movement and Mercedes makes generous use of damping cushions for isolation between engine and body.

Found this image online.....The strut mount bracket is a possibilty but the solid heim joints on this damper design are not the best solution for improving engine damping while also maintaining engine - body isolation. Moreover, this unit is apparently mounted without a counterpart which excludes its use in my mind. Would prefer a configuration that maintains engine top cover..

Last edited by YODAONE; 08-07-16 at 08:25 PM.

#7

The OEM mounts failing over age is not a design flaw, but rather a consideration. If you want extremely smooth and noise/vibration free performance, you give up longevity. The fact the OEM engine mounts easily last 120k miles, or ~8-10 years+ is a testament to Lexus' engineering.

Unless you are prepared to endure more vibration/noise from the additional mount that will serve to stiffen the engine cradle, or redesign the mounts (good luck) I would advise against this modification. The mercedes was designed in the 70s without CAD/CAM tools, not the most effective method though they did some amazing htings.

1/10 would not apply to the LS400.

Unless you are prepared to endure more vibration/noise from the additional mount that will serve to stiffen the engine cradle, or redesign the mounts (good luck) I would advise against this modification. The mercedes was designed in the 70s without CAD/CAM tools, not the most effective method though they did some amazing htings.

1/10 would not apply to the LS400.

Trending Topics

#8

Lexus Champion

Thread Starter

The OEM mounts failing over age is not a design flaw, but rather a consideration. If you want extremely smooth and noise/vibration free performance, you give up longevity. The fact the OEM engine mounts easily last 120k miles, or ~8-10 years+ is a testament to Lexus' engineering.

Unless you are prepared to endure more vibration/noise from the additional mount that will serve to stiffen the engine cradle, or redesign the mounts (good luck) I would advise against this modification. The mercedes was designed in the 70s without CAD/CAM tools, not the most effective method though they did some amazing htings.

1/10 would not apply to the LS400.

Unless you are prepared to endure more vibration/noise from the additional mount that will serve to stiffen the engine cradle, or redesign the mounts (good luck) I would advise against this modification. The mercedes was designed in the 70s without CAD/CAM tools, not the most effective method though they did some amazing htings.

1/10 would not apply to the LS400.

In many ways; engine, interior integrity they overshot the mark.

In certain areas such as suspension integrity, hardware (production efficient tapered thread cutting fasteners), electrical (ie grounding) they didn't put the ribbon on the package.

Forum posts address these various issues...

While Toyota made a major investment into Lexus engine mounts, it did not fully engineer ways to minimize torque movement of the engine... (never mind what happens to the mounts in short order after several off the line full throttle bursts).. Rubber by itself cannot both fully isolate and control movement of the engine.

I owned a 380 SEL that had these mini engine shock adsorbers and the engine was arguably as smooth, if not smoother at idle than the LS400... sound isolation is another story.

Mercedes used 4 dampening cushions on their two engine dampeners.to achieve engine - body isolation.

What I do recall is the Mercedes engine did not wind up around before applying torque to the wheels (I notice it) and those motor mounts lasted 190, 000 miles...

Granted if you stomp on it hard the dampened motor mounts will more noticably impart engine torque into the chassis, which I suppose is what you look for when doing so, otherwise you will hardly know they are there...AND with the added safety benefit should an engine mount fail...

From that perspective the Lexus design is poor. No mechanical connection is maintained between engine and chassis once the Lexus mounts fail.. (even American V8's once had a sandwhich type mount with catchment hooks in the event of rubber delamination)

When I replaced mine (just acquired car) one side was completely separated from its threaded mounting plate and the other side was 75% separated...

Great isolation but simply an unsafe design.

If anyone has a resource or design please share.

Thanks.

#9

Plase show some empirical evidence or data to support your claim that the engine mounts are somehow unsafe or prone to immediate disintegration?

Where did you get the idea that even new mounts will collapse after " several off the line full throttle bursts"??? Myself and others have gone so far as launching the stock mounts while drag racing to no ill effect.

Where did you get the idea that even new mounts will collapse after " several off the line full throttle bursts"??? Myself and others have gone so far as launching the stock mounts while drag racing to no ill effect.

#11

Lexus Champion

Thread Starter

Plase show some empirical evidence or data to support your claim that the engine mounts are somehow unsafe or prone to immediate disintegration?

Where did you get the idea that even new mounts will collapse after " several off the line full throttle bursts"??? Myself and others have gone so far as launching the stock mounts while drag racing to no ill effect.

Where did you get the idea that even new mounts will collapse after " several off the line full throttle bursts"??? Myself and others have gone so far as launching the stock mounts while drag racing to no ill effect.

See;

https://www.clublexus.com/forums/attachments/ls-1st-and-2nd-gen-1990-2000/354052d1423216960-check-your-engine-and-transmission-mounts-20150205_222452.jpg

Upon complete failure there is no safeguard or catchment mechanism and, simply put, the engine is no longer attached at that position to the body.

The opposing engine mount is not far behind...never mind the transmission mount which does not possess

a safety catchment mechanism either.

See;

https://www.clublexus.com/forums/attachments/ls-1st-and-2nd-gen-1990-2000/354054d1423217023-check-your-engine-and-transmission-mounts-20150205_221550.jpg

I stand by my position that this is a poor design because failure creates an unsafe condition.

In view of Toyotas well publicized product liabilty lawsuits (deaths) and recalls, I am not bashful about calling Toyota out on an engine mount that could have been more fully designed to anticipate primary failure...whenever and however that failure may occur.

If you choose not to agree, then we agree to disagree.

Meanwhile, the purpose of original posting was to solicit input on the propsed project.

[/I]

This is a failed LS400 transmission mount depicting complete separation upon failure. Photo courtesy of ClubLexus

Last edited by YODAONE; 08-08-16 at 03:06 PM.

#12

I agree with some not so thoughtful engineering on some areas of these cars, like the Gen 1 lower ball joints, they should have done what they do on the later ones in that area. And yes they should have put something to catch the engine if the motor mount breaks. On older cars in the past for performance applications they used catch cables and chains. In any normal rotating engine application the driver side on rear wheel drive cars is the side that's being pulled up and that mount has to hold what ever max torque of the engine is when your demanding that power especially if you have some nice tires with grip. For a performance application these are a good idea as long as you don't butcher the car body to install them, if using existing holes to attach them then they would be ok. I've seen industrial applications with motor mounts designed to catch the movement from a broken mount.

#13

Upon complete failure there is no safeguard or catchment mechanism and, simply put, the engine is no longer attached at that position to the body.

The opposing engine mount is not far behind...never mind the transmission mount which does not possess

I stand by my position that this is a poor design because failure creates an unsafe condition.

In view of Toyotas well publicized product liabilty lawsuits (deaths) and recalls, I am not bashful about calling Toyota out on an engine mount that could have been more fully designed to anticipate primary failure...whenever and however that failure may occur.

The opposing engine mount is not far behind...never mind the transmission mount which does not possess

I stand by my position that this is a poor design because failure creates an unsafe condition.

In view of Toyotas well publicized product liabilty lawsuits (deaths) and recalls, I am not bashful about calling Toyota out on an engine mount that could have been more fully designed to anticipate primary failure...whenever and however that failure may occur.

Show me one documented LS400 motor mount failure resulting in any kind of unsafe situation. Accident, collision, engine fell out, etc. One case that has been documented beyond a reasonable doubt that was caused by failed engine mounts.

Without that, without any data or examples or actual unsafe occurrences you're literally just spewing bunk claims that has no merit or value.

This is literally a case of "This doesn't seem right, therefore it must be wrong and remedied" without any real engineering basis. To clarify, your OBSERVATIONS are just that, they are not a replacement for an empirical study.

The LS400 engine mount design is perfectly safe and reasonably met the compromises needed at the time of production. Is improvement possible? Sure, but unless you have a sizable R&D budget or extensive engineering knowledge I would leave the hydraulic/active/new age engine mounts to Porsche.

#15

Driver School Candidate

Join Date: Nov 2006

Location: wa

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

This is only a useful addition to a very specific kind of car. I will illuminate you. The specific kind of car i am referencing is a high performance race car with a manual transmission. An automatic luxury car is not the place for this kind of performance part. The reason is due to the consideration of NVH (noise vibration harshness). When you directly link (yes even with a "shock absorber") you induce all kinds of noise into the chassis. That goes against all the engineering that went into the car. Yes engine mounts do fail. That is normal. Replace them. Your engine isnt going to go flying out of the car. Even with massively broken ones. The fact is you will be alerted to the fact that they are broken far before they become a problem. Secondly with out engine braking ability produced by a manual transmission you really gain nothing from having that brace there. An engine winding up under load really doesnt make the engine transmission assembly move very much. Its engine braking that really gets things rocking under there. So unless your ls is a manual i wouldnt worry about this at all.