Need help with telescopic wheel

#61

Hi Johnno92, in post 56 you mention "you may need to remove the gear assembly cover".

Is it the the other two screws showin removed in that same picture?

Or is it the area in the middle of this pic?

Thanks, still can't get that motor out yet....have all screws off but one holding the motor together.

Is it the the other two screws showin removed in that same picture?

Or is it the area in the middle of this pic?

Thanks, still can't get that motor out yet....have all screws off but one holding the motor together.

#62

Sweet Success!!!

I started reassembling all my notes. Finally noticed the message in the "gray text box" of post 19...when you're reading/skimming so many posts over the months (and following long days at work) guess I "filtered" out some stuff. :-)

In that "quote box" of post 19, he had said his titl-motor stopped altogether, and that he disconnected the battery with key in ignition (don't know why) ...meaning he was able to get the motor out without it turning in any way. I.followed what he did from there and got it out now. Phew!

Also in Johnno's pics in post 21, I could tell he pulled the gearbox open...and information helped a lot.

I look forward to a day of cleaning and re-greasing tomorrow. Yay!

I started reassembling all my notes. Finally noticed the message in the "gray text box" of post 19...when you're reading/skimming so many posts over the months (and following long days at work) guess I "filtered" out some stuff. :-)

In that "quote box" of post 19, he had said his titl-motor stopped altogether, and that he disconnected the battery with key in ignition (don't know why) ...meaning he was able to get the motor out without it turning in any way. I.followed what he did from there and got it out now. Phew!

Also in Johnno's pics in post 21, I could tell he pulled the gearbox open...and information helped a lot.

I look forward to a day of cleaning and re-greasing tomorrow. Yay!

Last edited by johnnyho; 12-27-14 at 01:14 PM.

#63

In case useful somewhere, somehow. There's not a lot of info on this other than what we figure out ourselves here, to my knowledge?. If someone has knowledge or experience to add more, please do! I have the manuals for my car etc...."official data" assumes you replace the column as a unit.

#64

Driver School Candidate

Join Date: Nov 2013

Location: British Columbia

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

hey just wondering so, i'm having these problems now when the temperature dropped to -8 Celsius. does greasing work? does the motor get stuck because of cold weather? im parked outside and it was fine yesterday before the temperature dropped

#65

I started a new thread on this, to see if got some fresh "eyes" might help.

I'm still in the throes of this, but "could" be on to something I'll try to explain if works...or at least throw more light on,

It will be here:

https://www.clublexus.com/forums/gs-...se-v2-0-a.html

Sorry I can't offer more at the moment, but working fast as I can - have to :-)

Consensus I have seen is that the re-greasing works temporarily. Love to hear differently, or if anyone knows how to buy a new motor by itself. Or if anyone has experience replacing the "brushes" (which is what I'm trying next).

I "feel ya", and thanks for chiming in :-)

I'm still in the throes of this, but "could" be on to something I'll try to explain if works...or at least throw more light on,

It will be here:

https://www.clublexus.com/forums/gs-...se-v2-0-a.html

Sorry I can't offer more at the moment, but working fast as I can - have to :-)

Consensus I have seen is that the re-greasing works temporarily. Love to hear differently, or if anyone knows how to buy a new motor by itself. Or if anyone has experience replacing the "brushes" (which is what I'm trying next).

I "feel ya", and thanks for chiming in :-)

Last edited by johnnyho; 12-27-14 at 01:18 PM.

#66

Advanced

Johnnyho,

Thanks for your determination. We will figure this thing out someday, lol. Anyway, this morning my steering wheel was stuck in the” up” position, and I felt like I was driving a school bus. So, I decided to investigate further to try and understand the tilt and how it works. I went to Sewell to the diagram of the mechanism.

This picture below is what I believe to be the “lube points” because these all have “gear teeth or ribbed stafts”. When the steering wheel needs to be moved many moving parts are required for this to happen.

Thanks for your determination. We will figure this thing out someday, lol. Anyway, this morning my steering wheel was stuck in the” up” position, and I felt like I was driving a school bus. So, I decided to investigate further to try and understand the tilt and how it works. I went to Sewell to the diagram of the mechanism.

This picture below is what I believe to be the “lube points” because these all have “gear teeth or ribbed stafts”. When the steering wheel needs to be moved many moving parts are required for this to happen.

Last edited by wbmx1981; 12-09-14 at 07:10 AM.

#67

Advanced

I also noticed on Sewell that they use the words “bush” and “shim”, to me these could be culprits for stuck or seized steering tilt controls.

Last edited by wbmx1981; 12-09-14 at 07:11 AM.

#69

Advanced

#70

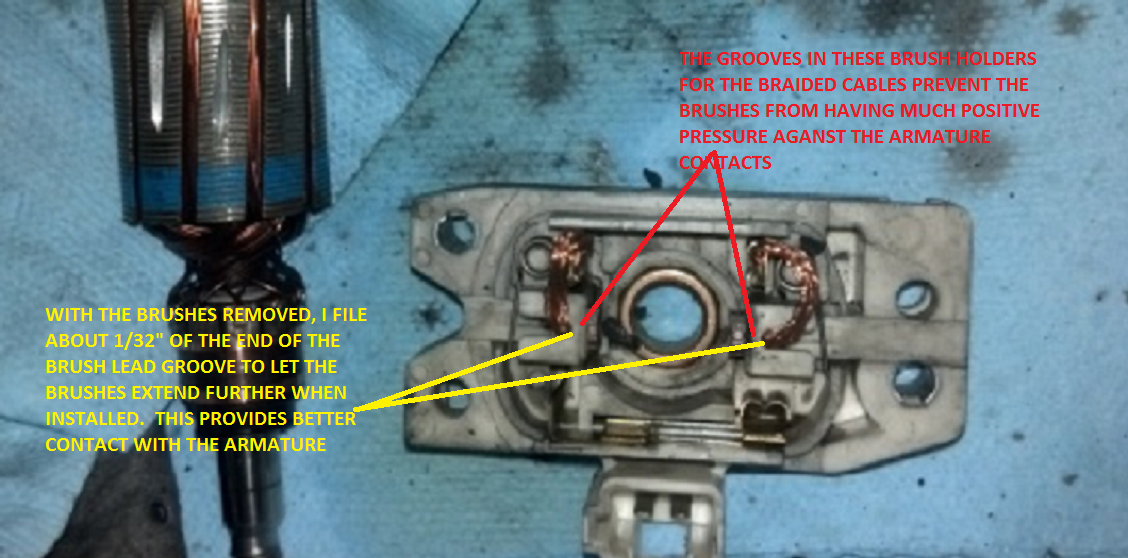

I wouldnt file the brushes. They are uber soft and you dont want to loose any length to them. also, they have the curve worn into them like they are supposed to. I just use 0000 steel wool on the armature contacts to make sure they are clean and smooth and then file the little slots in the plastic brush holders a little so the brushes can slide a tad bit further torwards eachother. Since Ive done this, my tilt column has worked like new.

Right before they quit working it started sounding slower and louder..kind of like a growl. Once it got cold...the tilt did not work at all. I filed the holder, cleaned them good, and used some lithium grease and has worked perfect since. Much quieter and sounds like a normal column, not one thats ticked off.

Right before they quit working it started sounding slower and louder..kind of like a growl. Once it got cold...the tilt did not work at all. I filed the holder, cleaned them good, and used some lithium grease and has worked perfect since. Much quieter and sounds like a normal column, not one thats ticked off.

#71

Advanced

I wouldnt file the brushes. They are uber soft and you dont want to loose any length to them. also, they have the curve worn into them like they are supposed to. I just use 0000 steel wool on the armature contacts to make sure they are clean and smooth and then file the little slots in the plastic brush holders a little so the brushes can slide a tad bit further torwards eachother. Since Ive done this, my tilt column has worked like new.

Right before they quit working it started sounding slower and louder..kind of like a growl. Once it got cold...the tilt did not work at all. I filed the holder, cleaned them good, and used some lithium grease and has worked perfect since. Much quieter and sounds like a normal column, not one thats ticked off.

Right before they quit working it started sounding slower and louder..kind of like a growl. Once it got cold...the tilt did not work at all. I filed the holder, cleaned them good, and used some lithium grease and has worked perfect since. Much quieter and sounds like a normal column, not one thats ticked off.

#72

Wow! Excellent. Thanks so much for sharing this Keykeeper!!

Webmx1981 that's awesome info, too! The diagrams kinda show what you would run into getting under the hex-nuts in the 2nd pic of post #63...not "too scary" looking in there. I had seen someone working with putting grease just before and behind that piece, then working the telescoping motor back and forth to get the new grease inside there (till it stopped squealing, for him).

That black plastic piece on the underside seems to be part# 89227 in your diagram, and says refer to figure 84-01 ...wonder where that is?

I've got new brushes I am looking at soldering in, soon as I can get to it. Planning on posting pics of the spring mechanism, AND that I also noticed part of my badly "unbraided" brush-wire had worked its way over the face of the brush... kinda mashed partly onto it. Where it comes into contact with the rotating armature I presume.

The new brushes I picked up seem close enough to the right width/heighth, however I'm thinking they're about 20% too long and I need to file them back. Guess I'd have to see if I can file that "curvature" into them at the same time.

Webmx1981 that's awesome info, too! The diagrams kinda show what you would run into getting under the hex-nuts in the 2nd pic of post #63...not "too scary" looking in there. I had seen someone working with putting grease just before and behind that piece, then working the telescoping motor back and forth to get the new grease inside there (till it stopped squealing, for him).

That black plastic piece on the underside seems to be part# 89227 in your diagram, and says refer to figure 84-01 ...wonder where that is?

I've got new brushes I am looking at soldering in, soon as I can get to it. Planning on posting pics of the spring mechanism, AND that I also noticed part of my badly "unbraided" brush-wire had worked its way over the face of the brush... kinda mashed partly onto it. Where it comes into contact with the rotating armature I presume.

The new brushes I picked up seem close enough to the right width/heighth, however I'm thinking they're about 20% too long and I need to file them back. Guess I'd have to see if I can file that "curvature" into them at the same time.

Last edited by johnnyho; 12-27-14 at 01:24 PM.

#73

You could use a fine rat tail file to put some curve into them. Just a slight curve. They WILL work with the flat edge though. I just noted not to file them as they would eventually wear back to the curve and that would make the original brushes even shorter. Im sure ebay or radio shack has brushes that could be used and then just solder the braids to the OEM contacts. I didnt want to fish around so I just filed them. Figure the motor only goes live for a few seconds so it would last a few more years before it completely died.

#74

Thanks Keykeeper, awesome observations!

I have some pics to post soon as I get a chance.

I definitely see where extending that notch will extend the brushes some more...maybe 1/16 to an 1/8th inch more life from(?) But I'm still not sure what that will buy in more years? - while definitely worthwhile(!) or in a pinch while you're in there.

I can tell now that my brushes are worn down by half...I think at full length they were 3/8 inches long (which is what I'll file my new .5 inch ones down to). Actually I will go ahead and post a pic now to explain why I guess that measurement. If anyone sees differently from my guesstimation please chime in.

One could extrapolate an estimate that over 12 years my brushes lost 1.5 eighths of an inch ...so maybe getting that extra 16th or even 8th(max?) of an inch, extending that slot, could buy several more years?

I have the brushes, so going ahead like you said and sauter onto the existing connectors...plan on using a grinding wheel to remove the necessary length then try to round a little with a very small set of files....or maybe a rounded dremel grinder. Then cut a slot on the back of it for the spring to sit into (like the original brush has). I just hope the new wire lead is up to the task as well.

I have some pics to post soon as I get a chance.

I definitely see where extending that notch will extend the brushes some more...maybe 1/16 to an 1/8th inch more life from(?) But I'm still not sure what that will buy in more years? - while definitely worthwhile(!) or in a pinch while you're in there.

I can tell now that my brushes are worn down by half...I think at full length they were 3/8 inches long (which is what I'll file my new .5 inch ones down to). Actually I will go ahead and post a pic now to explain why I guess that measurement. If anyone sees differently from my guesstimation please chime in.

One could extrapolate an estimate that over 12 years my brushes lost 1.5 eighths of an inch ...so maybe getting that extra 16th or even 8th(max?) of an inch, extending that slot, could buy several more years?

I have the brushes, so going ahead like you said and sauter onto the existing connectors...plan on using a grinding wheel to remove the necessary length then try to round a little with a very small set of files....or maybe a rounded dremel grinder. Then cut a slot on the back of it for the spring to sit into (like the original brush has). I just hope the new wire lead is up to the task as well.

Last edited by johnnyho; 12-27-14 at 01:50 PM.

#75

this is what i like to see.

maybe if you could get the measurement of the brush (ive no idea if theres a standard size to them) but it looks like rc car sized and i know those are really cheap to get. might be something you'd want to look into

maybe if you could get the measurement of the brush (ive no idea if theres a standard size to them) but it looks like rc car sized and i know those are really cheap to get. might be something you'd want to look into